T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

| Availability: | |

|---|---|

| Quantity: | |

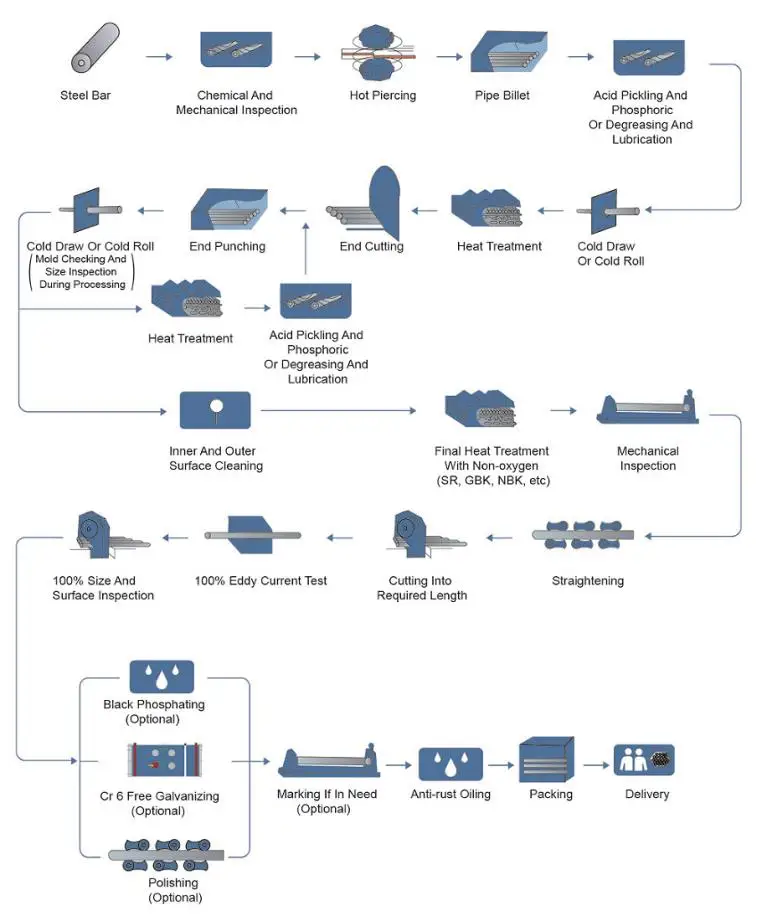

Detailed Image

Description

hydraulic tubing is used in a variety of applications where a liquid needs to be transferred from one point to another. The most common use for hydraulic pipe is in the automotive industry, where it is used to transfer fluids between different parts of a car. hydraulic tube is also used in the construction industry, where it is used to transfer concrete or other materials from one point to another.

Specifications

| Outside Diameter | 3mm-140mm |

| Thickness | 0.5-20mm |

| Material | 10#, 20#, 35#, 45#, 16Mn, 30CrMo, 20Cr, 20CrMo,15CrMo, 35CrMo, 42CrMo4, 20Mn, ST35,ST37,E235, ASTM11A, ST45, E255, A106A.B, ST55, CK45, S45C, Q345B, ST52, E355, S355j2, 4130, 4140, 4340, SCM440, SCM415 |

| Surface | bright annealing,black phosphated,galvanized |

| Standard | GB/T8713, GB/T3639, GB/T8162, GB/T8163, ASTM-A519, EN10305-1, EN10305-4, JIS-G3445, DIN2391, BS6323, GOST8734-75 |

| Processing | Cold rolled /cold drawn |

| Delivery Condition | (1) BK (+C): No heat treatment after last cold forming process; (2) BKW (+LC): After last heat treatment there is a light finishing pass (cold drawing); (3) BKS (+SR): After the final cold forming process the tubes are stress relieve annealed; (4) GBK (+A): After the final cold forming process the tubes are annealed in a controlled atmosphere; (5) NBK (+N): After the final cold forming process the tubes are annealed above the upper transformation point in a controlled atmosphere. |

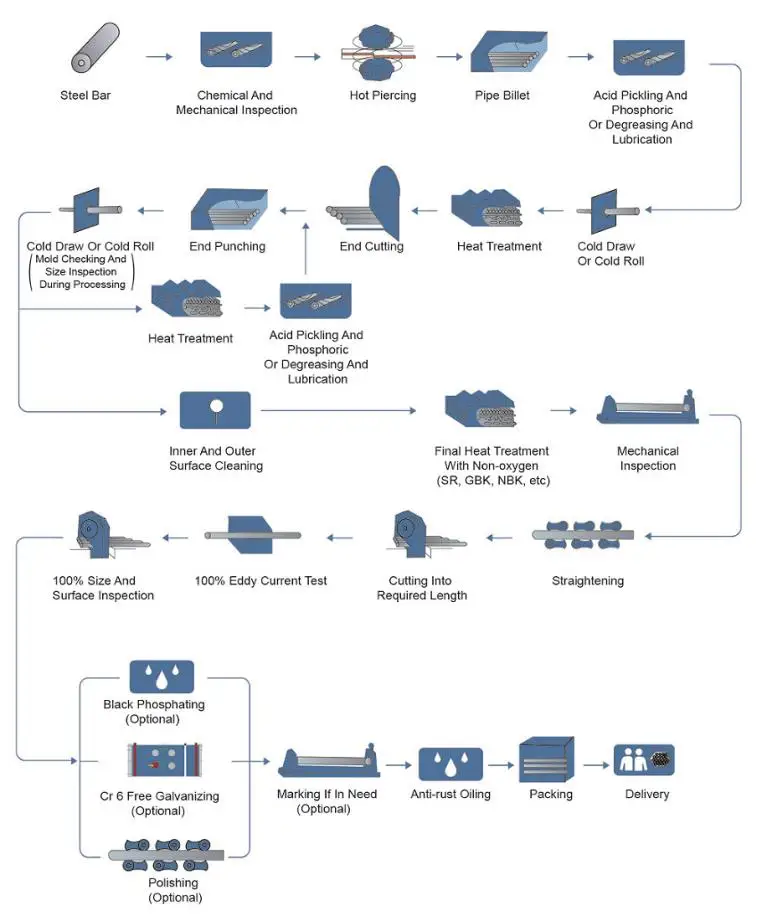

Detailed Image

Description

hydraulic tubing is used in a variety of applications where a liquid needs to be transferred from one point to another. The most common use for hydraulic pipe is in the automotive industry, where it is used to transfer fluids between different parts of a car. hydraulic tube is also used in the construction industry, where it is used to transfer concrete or other materials from one point to another.

Specifications

| Outside Diameter | 3mm-140mm |

| Thickness | 0.5-20mm |

| Material | 10#, 20#, 35#, 45#, 16Mn, 30CrMo, 20Cr, 20CrMo,15CrMo, 35CrMo, 42CrMo4, 20Mn, ST35,ST37,E235, ASTM11A, ST45, E255, A106A.B, ST55, CK45, S45C, Q345B, ST52, E355, S355j2, 4130, 4140, 4340, SCM440, SCM415 |

| Surface | bright annealing,black phosphated,galvanized |

| Standard | GB/T8713, GB/T3639, GB/T8162, GB/T8163, ASTM-A519, EN10305-1, EN10305-4, JIS-G3445, DIN2391, BS6323, GOST8734-75 |

| Processing | Cold rolled /cold drawn |

| Delivery Condition | (1) BK (+C): No heat treatment after last cold forming process; (2) BKW (+LC): After last heat treatment there is a light finishing pass (cold drawing); (3) BKS (+SR): After the final cold forming process the tubes are stress relieve annealed; (4) GBK (+A): After the final cold forming process the tubes are annealed in a controlled atmosphere; (5) NBK (+N): After the final cold forming process the tubes are annealed above the upper transformation point in a controlled atmosphere. |