T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

aluminium

ASTM, GB/T

6063, 6061, 7075, 6065

| Availability: | |

|---|---|

| Quantity: | |

Detailed Image

| Standard: | ||||

| ASTM, EN, JIS, DIN, GB/T, etc. GB/T 5237, EN12020-1.2, ASTM B85-96, JIS H5302, Etc | ||||

| Material Grade: | ||||

| 1000 series: | 1050,1060,1070,1080,1100,1435, etc. | |||

| 2000 series: | 2011, 2014,2017,2024, etc. | |||

| 3000 series: | 3002,3003,3104,3204,3030 , etc. | |||

| 5000 series: | 5005,5025,5040,5056,5083, etc. | |||

| 6000 series: | 6101,6003,6061,6063,6020,6201,6262,6082, etc. | |||

| 7000 series: | 7003,7005,7050,7075, etc. | |||

Specification

| Size: | Outer Diameter:3-250mm Wall Thickness: 0.3-50mm | |||

| Shape: | round, oval, square, irregular, customized | |||

| Color: | Nature, silver, bronze, champagne, black, golden, etc. | |||

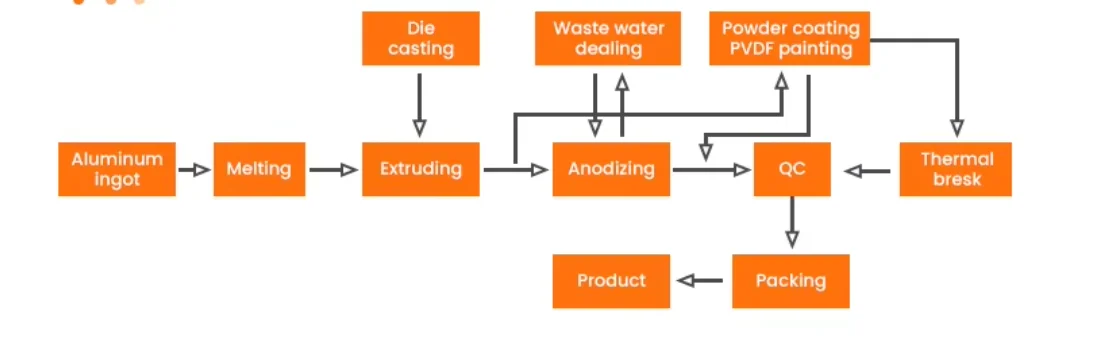

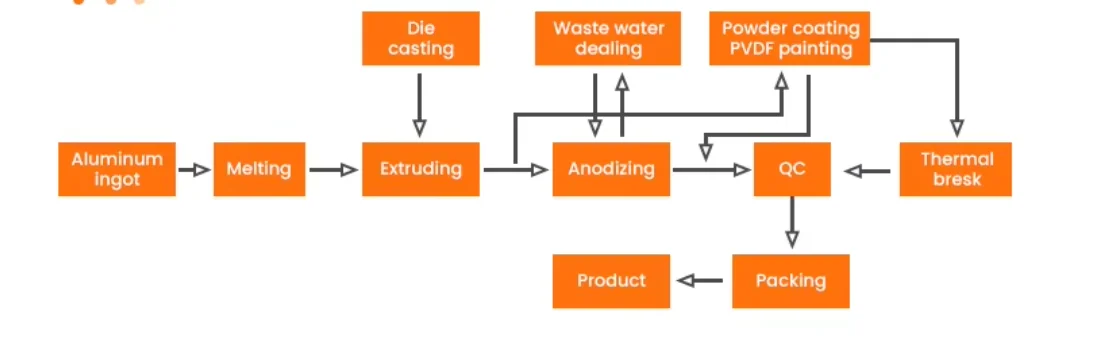

| Surface Treatment: | Mill finished , anodized , powder coating, Sand blast, etc. | |||

| Status | T3-T8 Treatments | |||

Strength: Aluminium 6065 and 7075 are both high - strength alloys2. The 6065 alloy, with silicon and magnesium as its main alloying elements, has good strength and ductility1. The 7075 alloy, a cold - worked forging alloy, contains zinc, magnesium, and a small amount of copper and chromium, giving it extremely high strength, much higher than that of mild steel2. It is one of the strongest commercial alloys available2.

Corrosion Resistance: Both alloys have excellent corrosion resistance, making them suitable for use in harsh environments1. The anodized treatment further enhances this property, forming a dense aluminum oxide film on the surface that protects the tube from rust and chemical corrosion. This is particularly important for applications where the tube may be exposed to moisture, chemicals, or salt - water, such as in marine, chemical, and outdoor applications1.

Thermal Conductivity: Aluminium has good thermal conductivity, and both 6065 and 7075 alloys maintain this characteristic1. This makes them ideal for applications requiring efficient heat transfer, such as in heat - exchange systems or high - temperature environments1.

High Precision: Our production process ensures high - precision dimensions and tight tolerances, meeting the strictest requirements of various industries. Whether you need the tube for precise mechanical applications, aerospace components, or high - end architectural projects, our high - precision round tubes can provide reliable support.

Polished Surface: The polished finish of the tube gives it a smooth and shiny surface, enhancing its aesthetic appeal. This not only makes the product look more attractive but also facilitates cleaning and maintenance, making it suitable for applications where appearance is important, such as in decorative and interior design projects.

Anodized Coating: The anodized treatment not only improves the corrosion resistance and wear resistance of the tube but also allows for a variety of colors and finishes, providing more design options for different applications. Whether you prefer a classic silver - white, a trendy black, or a custom - colored finish, we can meet your specific requirements.

Aerospace and Automotive Industries: The high strength - to - weight ratio of aluminium 6065 and 7075 makes them ideal materials for aerospace and automotive applications1. They can help reduce the weight of aircraft and vehicles while maintaining structural strength, improving fuel efficiency and performance.

Mechanical Equipment and Engineering: In mechanical equipment manufacturing and engineering projects, these round tubes are widely used due to their high strength and durability. They can be used to make machine components, structural supports, and conveyor systems, among other things, ensuring the reliable operation of equipment and structures.

Architectural and Decorative Applications: The aesthetic appeal and corrosion resistance of the polished anodized round tubes make them popular in architectural and decorative applications. They can be used for curtain walls, handrails, decorative columns, and other architectural elements, adding a touch of elegance and modernity to buildings.

Product packaging

Upgrade your industrial projects with our high-quality 6061 & 6063 Aluminum Tubes. Whether you need standard sizes or fully customized solutions, we’ve got you covered.

Detailed Image

| Standard: | ||||

| ASTM, EN, JIS, DIN, GB/T, etc. GB/T 5237, EN12020-1.2, ASTM B85-96, JIS H5302, Etc | ||||

| Material Grade: | ||||

| 1000 series: | 1050,1060,1070,1080,1100,1435, etc. | |||

| 2000 series: | 2011, 2014,2017,2024, etc. | |||

| 3000 series: | 3002,3003,3104,3204,3030 , etc. | |||

| 5000 series: | 5005,5025,5040,5056,5083, etc. | |||

| 6000 series: | 6101,6003,6061,6063,6020,6201,6262,6082, etc. | |||

| 7000 series: | 7003,7005,7050,7075, etc. | |||

Specification

| Size: | Outer Diameter:3-250mm Wall Thickness: 0.3-50mm | |||

| Shape: | round, oval, square, irregular, customized | |||

| Color: | Nature, silver, bronze, champagne, black, golden, etc. | |||

| Surface Treatment: | Mill finished , anodized , powder coating, Sand blast, etc. | |||

| Status | T3-T8 Treatments | |||

Strength: Aluminium 6065 and 7075 are both high - strength alloys2. The 6065 alloy, with silicon and magnesium as its main alloying elements, has good strength and ductility1. The 7075 alloy, a cold - worked forging alloy, contains zinc, magnesium, and a small amount of copper and chromium, giving it extremely high strength, much higher than that of mild steel2. It is one of the strongest commercial alloys available2.

Corrosion Resistance: Both alloys have excellent corrosion resistance, making them suitable for use in harsh environments1. The anodized treatment further enhances this property, forming a dense aluminum oxide film on the surface that protects the tube from rust and chemical corrosion. This is particularly important for applications where the tube may be exposed to moisture, chemicals, or salt - water, such as in marine, chemical, and outdoor applications1.

Thermal Conductivity: Aluminium has good thermal conductivity, and both 6065 and 7075 alloys maintain this characteristic1. This makes them ideal for applications requiring efficient heat transfer, such as in heat - exchange systems or high - temperature environments1.

High Precision: Our production process ensures high - precision dimensions and tight tolerances, meeting the strictest requirements of various industries. Whether you need the tube for precise mechanical applications, aerospace components, or high - end architectural projects, our high - precision round tubes can provide reliable support.

Polished Surface: The polished finish of the tube gives it a smooth and shiny surface, enhancing its aesthetic appeal. This not only makes the product look more attractive but also facilitates cleaning and maintenance, making it suitable for applications where appearance is important, such as in decorative and interior design projects.

Anodized Coating: The anodized treatment not only improves the corrosion resistance and wear resistance of the tube but also allows for a variety of colors and finishes, providing more design options for different applications. Whether you prefer a classic silver - white, a trendy black, or a custom - colored finish, we can meet your specific requirements.

Aerospace and Automotive Industries: The high strength - to - weight ratio of aluminium 6065 and 7075 makes them ideal materials for aerospace and automotive applications1. They can help reduce the weight of aircraft and vehicles while maintaining structural strength, improving fuel efficiency and performance.

Mechanical Equipment and Engineering: In mechanical equipment manufacturing and engineering projects, these round tubes are widely used due to their high strength and durability. They can be used to make machine components, structural supports, and conveyor systems, among other things, ensuring the reliable operation of equipment and structures.

Architectural and Decorative Applications: The aesthetic appeal and corrosion resistance of the polished anodized round tubes make them popular in architectural and decorative applications. They can be used for curtain walls, handrails, decorative columns, and other architectural elements, adding a touch of elegance and modernity to buildings.

Product packaging

Upgrade your industrial projects with our high-quality 6061 & 6063 Aluminum Tubes. Whether you need standard sizes or fully customized solutions, we’ve got you covered.