T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Titanium

ASTM B338

Gr1/Gr2/Gr5/GR9

| Availability: | |

|---|---|

| Quantity: | |

Detailed Image

Product Information

| Name | Titanium Tube & Pipe | |||

| Material | Pure Titanium/ Titanium Alloy | |||

| Standard | GB/T 3624,GB/T 3625,GB/T 26057 ASTM B337,ASTM B338,ASTM B861,ASTM B862 JIS H 4630 | |||

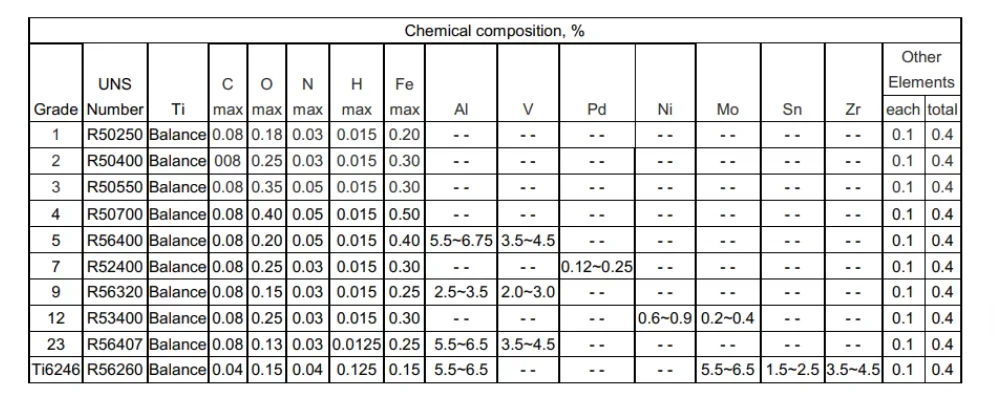

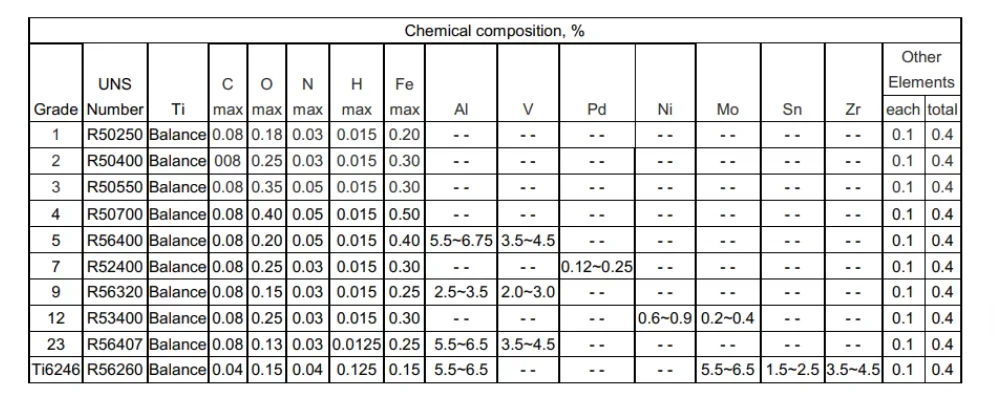

| Common Grade | National standard grades: TA1, TA2, TC4, TA9, TA18, TA10 American standard grades: GR1, GR2, GR5, GR7, GR9, GR12 | |||

| Size | Length: 50-6000mm or according to customer requirements | |||

| Outer diameter: 6-80mm or according to customer requirements | ||||

| Wall thickness: 0.35-10mm or according to customer requirements | ||||

| Section shape | Round / Square/Oval/Spiral/Bar | |||

| Surface | Bright annealing, Pickling,Polishing | |||

Product Features

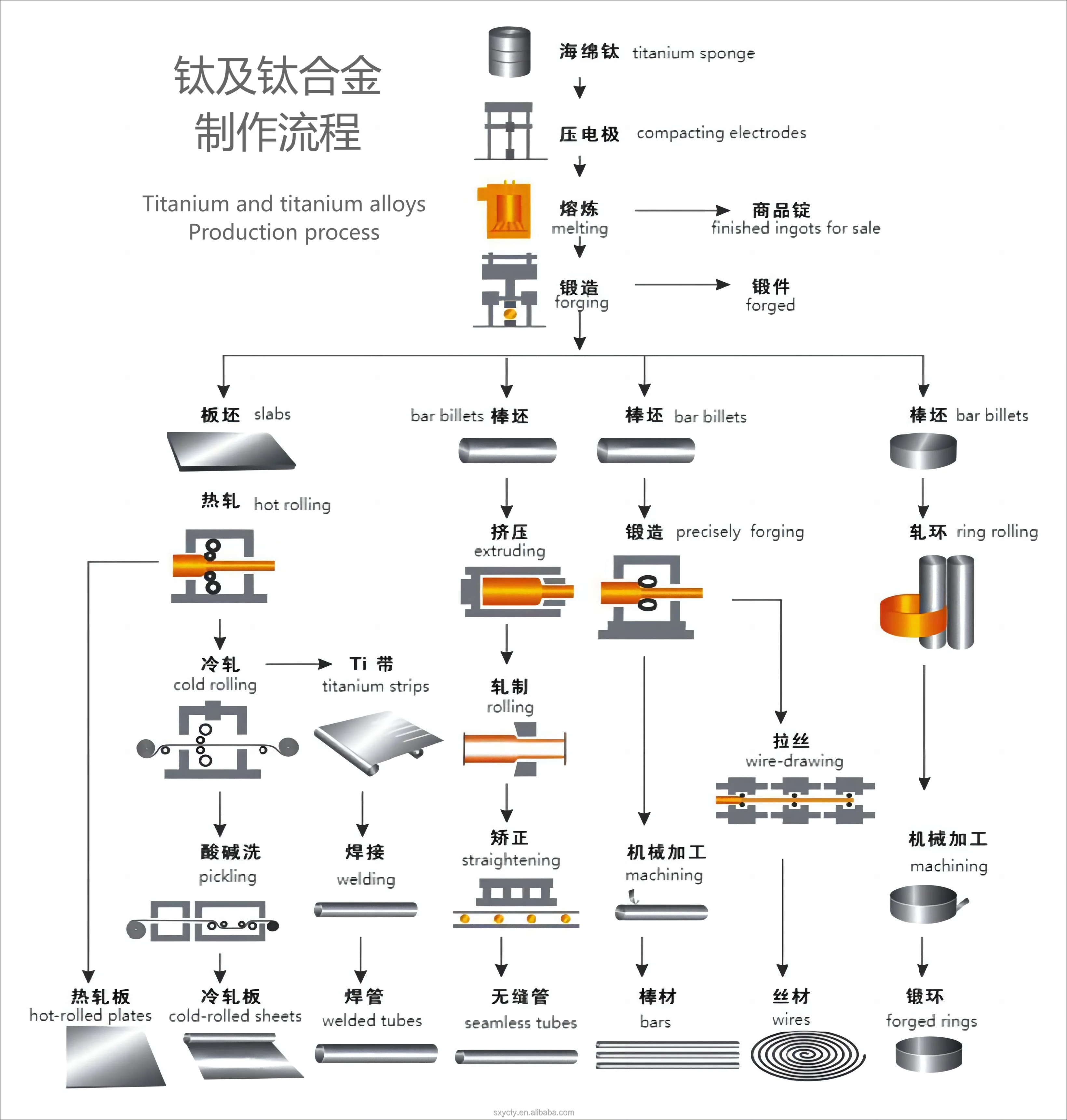

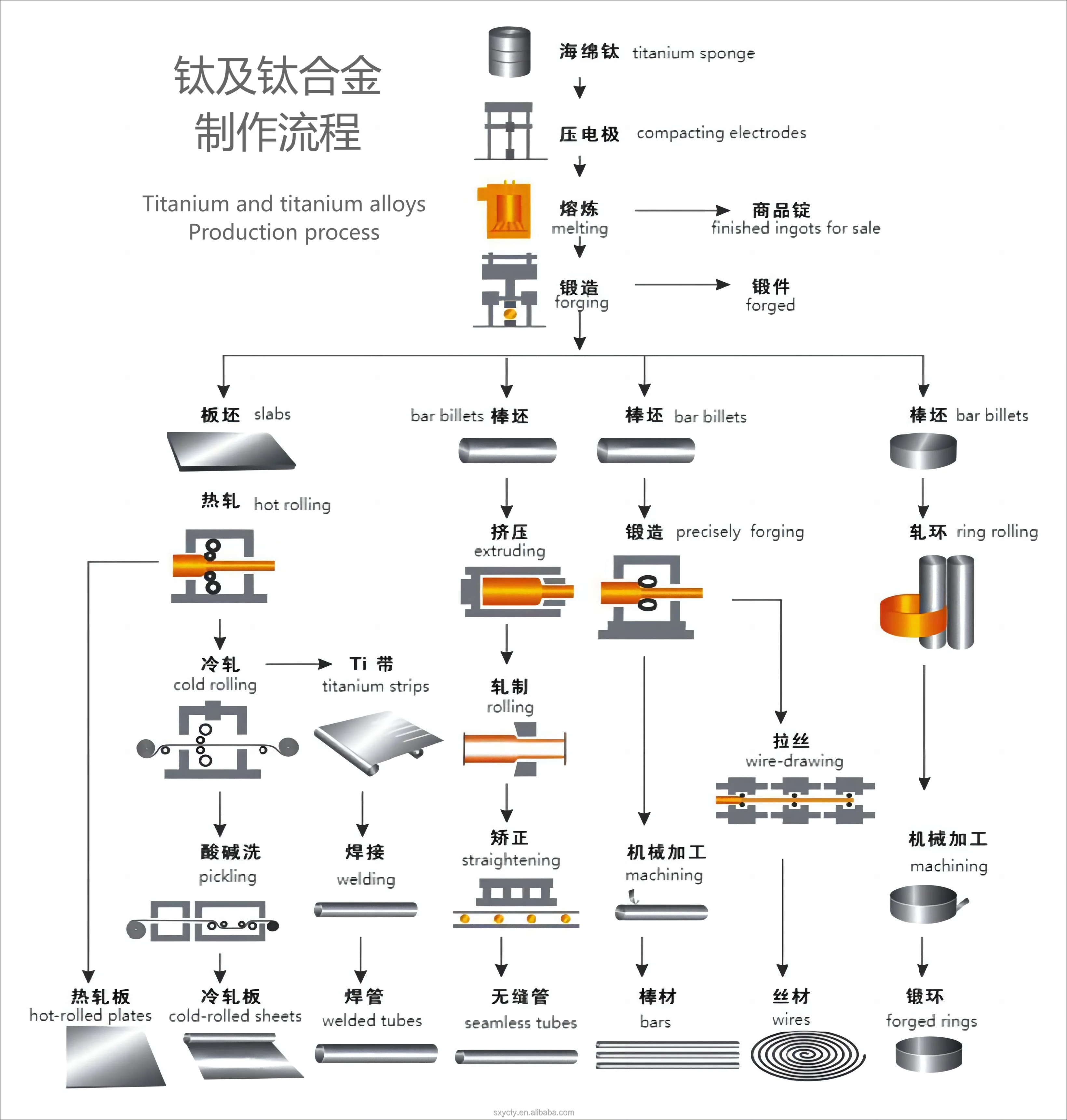

Top-quality materials, excellent performance

Made of pure titanium: Made of high-purity titanium, titanium has the characteristics of low density and high strength, which ensures the strength of the pipeline while reducing the overall weight, making it easy to install and transport. At the same time, titanium has excellent corrosion resistance and can resist the erosion of various corrosive media, including impurities and chemicals in oils, ensuring that the pipeline will not corrode and leak during long-term use, extending the service life of the pipeline and reducing maintenance costs.

Meet high standards: Strictly follow ASTM B338 and ASTM B861 standards for production. These two standards have strict regulations on the chemical composition, physical properties, dimensional tolerances, etc. of titanium tubes. By following these standards, our titanium tubes ensure that each batch of products has stable quality and reliable performance, and can meet the needs of fluid oil transportation in various industrial environments.

Pickling and polishing process, keep improving

Pickling treatment: The pickling process can remove the oxide scale, oil stains and other impurities on the surface of the titanium tube, giving the surface of the tube a clean and bright appearance. At the same time, pickling can also improve the microstructure of the pipe surface, improve its corrosion resistance and adhesion of subsequent treatment, and lay a good foundation for the subsequent polishing process.

Fine polishing: Advanced polishing technology is used to make the surface of the titanium tube reach a very high finish. The smooth surface can not only reduce the resistance of the fluid when it flows in the pipeline and improve the oil transportation efficiency, but also prevent impurities in the oil from adhering to the pipe wall, avoiding the risk of pipeline blockage and pollution. In addition, the polished surface has good wear resistance, can resist the scouring and friction of the oil flow, and maintain the stability of the performance of the pipe.

Wide range of application fields

Petrochemical industry: During the process of oil extraction, refining and transportation, our pure titanium oil pipeline can withstand high temperature, high pressure and corrosive media to ensure the safe transportation of oil. Whether it is an offshore oil platform, a land oil well or a pipeline system in a refinery, it can perform excellently.

Fine chemical field: For some fine chemical production processes that require high fluid purity, such as pharmaceuticals, cosmetics and other industries, pure titanium oil pipelines can avoid the contamination of oil products by pipeline materials due to their excellent corrosion resistance and surface finish, and ensure the quality and safety of products.

Other industrial applications: It can also be used in oil delivery systems in aerospace, shipbuilding and other fields. In these fields, there are strict requirements on the weight, strength and corrosion resistance of pipelines, and our pure titanium oil pipelines can meet these requirements and provide guarantees for the stable operation of equipment.

Applications

Bicycle frames

Lightweight frames for road bikes, mountain bikes and hybrid bikes.

Handlebars

Strong and shock-absorbing handlebars for a comfortable grip.

Seat tubes

Lightweight and corrosion-resistant seat tubes for improved riding performance.

Custom bikes

Suitable for high-end custom bike designs that combine beauty and functionality.

Other components

Key bicycle components such as front forks and chain stays.

Detailed Image

Product Information

| Name | Titanium Tube & Pipe | |||

| Material | Pure Titanium/ Titanium Alloy | |||

| Standard | GB/T 3624,GB/T 3625,GB/T 26057 ASTM B337,ASTM B338,ASTM B861,ASTM B862 JIS H 4630 | |||

| Common Grade | National standard grades: TA1, TA2, TC4, TA9, TA18, TA10 American standard grades: GR1, GR2, GR5, GR7, GR9, GR12 | |||

| Size | Length: 50-6000mm or according to customer requirements | |||

| Outer diameter: 6-80mm or according to customer requirements | ||||

| Wall thickness: 0.35-10mm or according to customer requirements | ||||

| Section shape | Round / Square/Oval/Spiral/Bar | |||

| Surface | Bright annealing, Pickling,Polishing | |||

Product Features

Top-quality materials, excellent performance

Made of pure titanium: Made of high-purity titanium, titanium has the characteristics of low density and high strength, which ensures the strength of the pipeline while reducing the overall weight, making it easy to install and transport. At the same time, titanium has excellent corrosion resistance and can resist the erosion of various corrosive media, including impurities and chemicals in oils, ensuring that the pipeline will not corrode and leak during long-term use, extending the service life of the pipeline and reducing maintenance costs.

Meet high standards: Strictly follow ASTM B338 and ASTM B861 standards for production. These two standards have strict regulations on the chemical composition, physical properties, dimensional tolerances, etc. of titanium tubes. By following these standards, our titanium tubes ensure that each batch of products has stable quality and reliable performance, and can meet the needs of fluid oil transportation in various industrial environments.

Pickling and polishing process, keep improving

Pickling treatment: The pickling process can remove the oxide scale, oil stains and other impurities on the surface of the titanium tube, giving the surface of the tube a clean and bright appearance. At the same time, pickling can also improve the microstructure of the pipe surface, improve its corrosion resistance and adhesion of subsequent treatment, and lay a good foundation for the subsequent polishing process.

Fine polishing: Advanced polishing technology is used to make the surface of the titanium tube reach a very high finish. The smooth surface can not only reduce the resistance of the fluid when it flows in the pipeline and improve the oil transportation efficiency, but also prevent impurities in the oil from adhering to the pipe wall, avoiding the risk of pipeline blockage and pollution. In addition, the polished surface has good wear resistance, can resist the scouring and friction of the oil flow, and maintain the stability of the performance of the pipe.

Wide range of application fields

Petrochemical industry: During the process of oil extraction, refining and transportation, our pure titanium oil pipeline can withstand high temperature, high pressure and corrosive media to ensure the safe transportation of oil. Whether it is an offshore oil platform, a land oil well or a pipeline system in a refinery, it can perform excellently.

Fine chemical field: For some fine chemical production processes that require high fluid purity, such as pharmaceuticals, cosmetics and other industries, pure titanium oil pipelines can avoid the contamination of oil products by pipeline materials due to their excellent corrosion resistance and surface finish, and ensure the quality and safety of products.

Other industrial applications: It can also be used in oil delivery systems in aerospace, shipbuilding and other fields. In these fields, there are strict requirements on the weight, strength and corrosion resistance of pipelines, and our pure titanium oil pipelines can meet these requirements and provide guarantees for the stable operation of equipment.

Applications

Bicycle frames

Lightweight frames for road bikes, mountain bikes and hybrid bikes.

Handlebars

Strong and shock-absorbing handlebars for a comfortable grip.

Seat tubes

Lightweight and corrosion-resistant seat tubes for improved riding performance.

Custom bikes

Suitable for high-end custom bike designs that combine beauty and functionality.

Other components

Key bicycle components such as front forks and chain stays.