T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon stainless Steel

ASTM A179 ASTM A269 EN10305-1 EN10216-5

as per request

| Availability: | |

|---|---|

| Quantity: | |

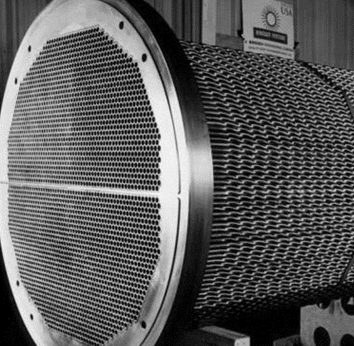

Product Images

Application

Description

The ASTM A179 Cold Drawn Heat Exchanger Steel Tube represents a pinnacle of engineering precision and material excellence, specifically tailored for the demanding requirements of heat exchanger applications. Crafted from high-quality steel and manufactured through a specialized cold drawing process in accordance with ASTM A179 standards, this seamless tube offers exceptional thermal conductivity, corrosion resistance, and reliability for critical heat transfer applications.

| Standard | OD(mm) | WT(mm) |

| ASTM A269 EN10305-1 EN10216-5 | 12.7 | 1.24 1.65 2.11 2.64 |

| 15.88 | 1.24 1.65 2.11 2.64 | |

| 19.05 | 1.24 1.65 2.11 2.64 | |

| 25.40 | 1.24 1.65 2.11 2.64 | |

| 38.10 | 1.24 1.65 2.11 2.64 | |

| Heat treatment | Aerobic annealing,Bright annealing | |

| Surface treatment | Oiled,Galvanized | |

Material Composition and Characteristics:

The ASTM A179 Cold Drawn Heat Exchanger Steel Tube is crafted from low-carbon steel, specifically designed for heat transfer applications.

Low-carbon steel composition ensures excellent thermal conductivity, allowing for efficient heat exchange while maintaining structural integrity and durability.

Efficient Heat Transfer: Our tubes are ideal for heat exchangers, providing superior heat transfer capabilities essential for industrial heating and cooling systems.

Durability: Designed to withstand the thermal and mechanical stresses of heat exchanger operation, ensuring long service life.

Reliable Performance: ASTM A179 tubes are perfect for condensers, ensuring efficient condensation of steam and other fluids.

Resistance to Corrosion: The corrosion-resistant properties of the material ensure reliable operation even in harsh environments.

High Pressure Tolerance: Suitable for use in boiler systems, our tubes can handle high pressures and temperatures, ensuring safety and efficiency.

Thermal Efficiency: Excellent thermal conductivity ensures efficient heat transfer, improving boiler performance.

Precision Cold Drawing Process:

The seamless tube undergoes a specialized cold drawing process as per ASTM A179 standards, wherein the steel billet is drawn through a series of dies to achieve the desired dimensions and mechanical properties.

Cold drawing imparts superior dimensional accuracy, surface finish, and mechanical strength to the tubing, ensuring uniformity and consistency in heat transfer performance.

Exceptional Thermal Conductivity:

The ASTM A179 Cold Drawn Heat Exchanger Steel Tube is renowned for its exceptional thermal conductivity, allowing for efficient heat transfer between the fluid streams within the heat exchanger.

High thermal conductivity ensures rapid and uniform heat exchange, optimizing energy efficiency and system performance.

Corrosion Resistance:

While low-carbon steel may be susceptible to corrosion in certain environments, the ASTM A179 tube can be further protected through surface coatings or treatments for enhanced corrosion resistance.

Proper maintenance and protective measures can extend the tube's lifespan and ensure consistent performance in corrosive heat exchanger applications.

Dimensional Accuracy and Surface Finish:

Precision cold drawing ensures tight dimensional tolerances, guaranteeing uniformity in wall thickness, outer diameter, and overall dimensions of the seamless tube.

The surface finish of the tubing is smooth and uniform, reducing fouling and scaling on the inner surface of the tube, which can impede heat transfer efficiency.

Mechanical Properties:

The cold drawing process imparts excellent mechanical properties to the seamless tube, including high tensile strength, yield strength, and hardness.

These properties ensure the tubing's ability to withstand mechanical stresses and pressure fluctuations encountered in heat exchanger applications, ensuring structural integrity and reliability.

Versatility and Customization:

The ASTM A179 Cold Drawn Heat Exchanger Steel Tube is available in various sizes, wall thicknesses, and configurations to accommodate diverse heat exchanger designs and operating conditions.

Customization options allow for tailoring the tubing to specific project requirements, ensuring compatibility and optimal performance in various heat transfer applications.

In summary, the ASTM A179 Cold Drawn Heat Exchanger Steel Tube offers unmatched quality, thermal conductivity, corrosion resistance, and reliability for a wide range of heat exchanger applications. Its compliance with ASTM A179 standards, precision manufacturing processes, and versatility make it the preferred choice for industries requiring high-performance tubing solutions for critical heat transfer applications.

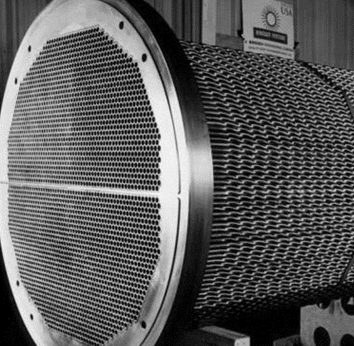

Product Images

Application

Description

The ASTM A179 Cold Drawn Heat Exchanger Steel Tube represents a pinnacle of engineering precision and material excellence, specifically tailored for the demanding requirements of heat exchanger applications. Crafted from high-quality steel and manufactured through a specialized cold drawing process in accordance with ASTM A179 standards, this seamless tube offers exceptional thermal conductivity, corrosion resistance, and reliability for critical heat transfer applications.

| Standard | OD(mm) | WT(mm) |

| ASTM A269 EN10305-1 EN10216-5 | 12.7 | 1.24 1.65 2.11 2.64 |

| 15.88 | 1.24 1.65 2.11 2.64 | |

| 19.05 | 1.24 1.65 2.11 2.64 | |

| 25.40 | 1.24 1.65 2.11 2.64 | |

| 38.10 | 1.24 1.65 2.11 2.64 | |

| Heat treatment | Aerobic annealing,Bright annealing | |

| Surface treatment | Oiled,Galvanized | |

Material Composition and Characteristics:

The ASTM A179 Cold Drawn Heat Exchanger Steel Tube is crafted from low-carbon steel, specifically designed for heat transfer applications.

Low-carbon steel composition ensures excellent thermal conductivity, allowing for efficient heat exchange while maintaining structural integrity and durability.

Efficient Heat Transfer: Our tubes are ideal for heat exchangers, providing superior heat transfer capabilities essential for industrial heating and cooling systems.

Durability: Designed to withstand the thermal and mechanical stresses of heat exchanger operation, ensuring long service life.

Reliable Performance: ASTM A179 tubes are perfect for condensers, ensuring efficient condensation of steam and other fluids.

Resistance to Corrosion: The corrosion-resistant properties of the material ensure reliable operation even in harsh environments.

High Pressure Tolerance: Suitable for use in boiler systems, our tubes can handle high pressures and temperatures, ensuring safety and efficiency.

Thermal Efficiency: Excellent thermal conductivity ensures efficient heat transfer, improving boiler performance.

Precision Cold Drawing Process:

The seamless tube undergoes a specialized cold drawing process as per ASTM A179 standards, wherein the steel billet is drawn through a series of dies to achieve the desired dimensions and mechanical properties.

Cold drawing imparts superior dimensional accuracy, surface finish, and mechanical strength to the tubing, ensuring uniformity and consistency in heat transfer performance.

Exceptional Thermal Conductivity:

The ASTM A179 Cold Drawn Heat Exchanger Steel Tube is renowned for its exceptional thermal conductivity, allowing for efficient heat transfer between the fluid streams within the heat exchanger.

High thermal conductivity ensures rapid and uniform heat exchange, optimizing energy efficiency and system performance.

Corrosion Resistance:

While low-carbon steel may be susceptible to corrosion in certain environments, the ASTM A179 tube can be further protected through surface coatings or treatments for enhanced corrosion resistance.

Proper maintenance and protective measures can extend the tube's lifespan and ensure consistent performance in corrosive heat exchanger applications.

Dimensional Accuracy and Surface Finish:

Precision cold drawing ensures tight dimensional tolerances, guaranteeing uniformity in wall thickness, outer diameter, and overall dimensions of the seamless tube.

The surface finish of the tubing is smooth and uniform, reducing fouling and scaling on the inner surface of the tube, which can impede heat transfer efficiency.

Mechanical Properties:

The cold drawing process imparts excellent mechanical properties to the seamless tube, including high tensile strength, yield strength, and hardness.

These properties ensure the tubing's ability to withstand mechanical stresses and pressure fluctuations encountered in heat exchanger applications, ensuring structural integrity and reliability.

Versatility and Customization:

The ASTM A179 Cold Drawn Heat Exchanger Steel Tube is available in various sizes, wall thicknesses, and configurations to accommodate diverse heat exchanger designs and operating conditions.

Customization options allow for tailoring the tubing to specific project requirements, ensuring compatibility and optimal performance in various heat transfer applications.

In summary, the ASTM A179 Cold Drawn Heat Exchanger Steel Tube offers unmatched quality, thermal conductivity, corrosion resistance, and reliability for a wide range of heat exchanger applications. Its compliance with ASTM A179 standards, precision manufacturing processes, and versatility make it the preferred choice for industries requiring high-performance tubing solutions for critical heat transfer applications.