T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon Steel

ASTM

ASTM A179

| Availability: | |

|---|---|

| Quantity: | |

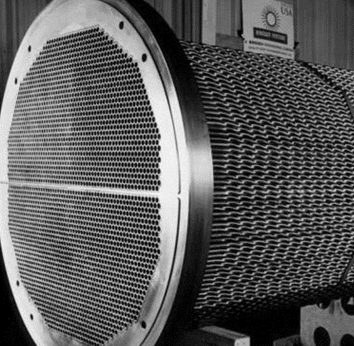

Product Images

| Standard | OD(mm) | WT(mm) |

ASTM A179 ASTM A269 EN10305-1 EN10216-5 | 12.7 | 1.24 1.65 2.11 2.64 |

| 15.88 | 1.24 1.65 2.11 2.64 | |

| 19.05 | 1.24 1.65 2.11 2.64 | |

| 25.40 | 1.24 1.65 2.11 2.64 | |

| 38.10 | 1.24 1.65 2.11 2.64 | |

| Heat treatment | Aerobic annealing,Bright annealing | |

| Surface treatment | Oiled,Galvanized | |

| These high performance tubes are available at dimensions between 12.70 mm and 38.10mm OD, which covers the majority of the standard sizes used. However, Fine Tubes also specializes in the development and production of small diameter thin wall tubing associated with applications in the aerospace and nuclear industries. Our minimum size here is just 0.98mm OD with a 0.04mm wall thickness. | ||

Including U Bent (U-Bend) Heat Exchanger Tubes, U Bent Tubes for Boiler.

Material: Carbon Steel, Stainless Steel, Copper, Alloy.

O.D.: 12.7 to 38.1mm

Bending Details: According to Bending Drawings.

Key Features

High-Quality Stainless Steel: Constructed from corrosion-resistant stainless steel, this heat exchanger tube offers superior durability and longevity, ensuring reliable performance in corrosive environments and high-temperature applications.

U Bend Configuration: The U bend design enhances heat transfer efficiency by maximizing the surface area available for thermal exchange, resulting in improved performance and energy efficiency of the heat exchanger system.

Precision Manufacturing: Crafted with precision machining techniques, the tube maintains tight dimensional tolerances and uniform wall thickness, ensuring consistent heat transfer performance and compatibility with standard heat exchanger components.

Smooth Internal Surface: The tube's smooth internal surface minimizes flow resistance and prevents the accumulation of debris or contaminants, promoting efficient fluid flow and reducing maintenance requirements.

Wide Range of Sizes and Configurations: Available in various sizes, diameters, and bend radii, the ASTM A269 Stainless U Bend Heat Exchanger Tube can be customized to meet specific application requirements, offering flexibility and versatility in heat exchanger design.

Corrosion Resistance: With its stainless steel construction and corrosion-resistant properties, the tube is capable of withstanding harsh operating conditions, including exposure to corrosive fluids and environments, ensuring long-term reliability and performance stability.

Application

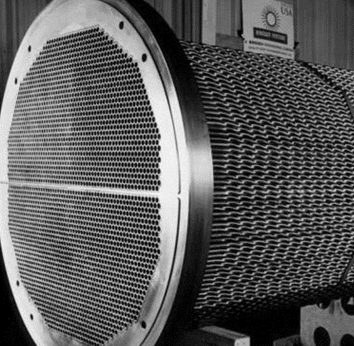

Product Images

| Standard | OD(mm) | WT(mm) |

ASTM A179 ASTM A269 EN10305-1 EN10216-5 | 12.7 | 1.24 1.65 2.11 2.64 |

| 15.88 | 1.24 1.65 2.11 2.64 | |

| 19.05 | 1.24 1.65 2.11 2.64 | |

| 25.40 | 1.24 1.65 2.11 2.64 | |

| 38.10 | 1.24 1.65 2.11 2.64 | |

| Heat treatment | Aerobic annealing,Bright annealing | |

| Surface treatment | Oiled,Galvanized | |

| These high performance tubes are available at dimensions between 12.70 mm and 38.10mm OD, which covers the majority of the standard sizes used. However, Fine Tubes also specializes in the development and production of small diameter thin wall tubing associated with applications in the aerospace and nuclear industries. Our minimum size here is just 0.98mm OD with a 0.04mm wall thickness. | ||

Including U Bent (U-Bend) Heat Exchanger Tubes, U Bent Tubes for Boiler.

Material: Carbon Steel, Stainless Steel, Copper, Alloy.

O.D.: 12.7 to 38.1mm

Bending Details: According to Bending Drawings.

Key Features

High-Quality Stainless Steel: Constructed from corrosion-resistant stainless steel, this heat exchanger tube offers superior durability and longevity, ensuring reliable performance in corrosive environments and high-temperature applications.

U Bend Configuration: The U bend design enhances heat transfer efficiency by maximizing the surface area available for thermal exchange, resulting in improved performance and energy efficiency of the heat exchanger system.

Precision Manufacturing: Crafted with precision machining techniques, the tube maintains tight dimensional tolerances and uniform wall thickness, ensuring consistent heat transfer performance and compatibility with standard heat exchanger components.

Smooth Internal Surface: The tube's smooth internal surface minimizes flow resistance and prevents the accumulation of debris or contaminants, promoting efficient fluid flow and reducing maintenance requirements.

Wide Range of Sizes and Configurations: Available in various sizes, diameters, and bend radii, the ASTM A269 Stainless U Bend Heat Exchanger Tube can be customized to meet specific application requirements, offering flexibility and versatility in heat exchanger design.

Corrosion Resistance: With its stainless steel construction and corrosion-resistant properties, the tube is capable of withstanding harsh operating conditions, including exposure to corrosive fluids and environments, ensuring long-term reliability and performance stability.

Application