T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon Steel

EN10305

E235 E355

| Availability: | |

|---|---|

| Quantity: | |

EN 10305-4 E235 E355 (+)N hydraulic black phosphate line seamless pipe manufacturer

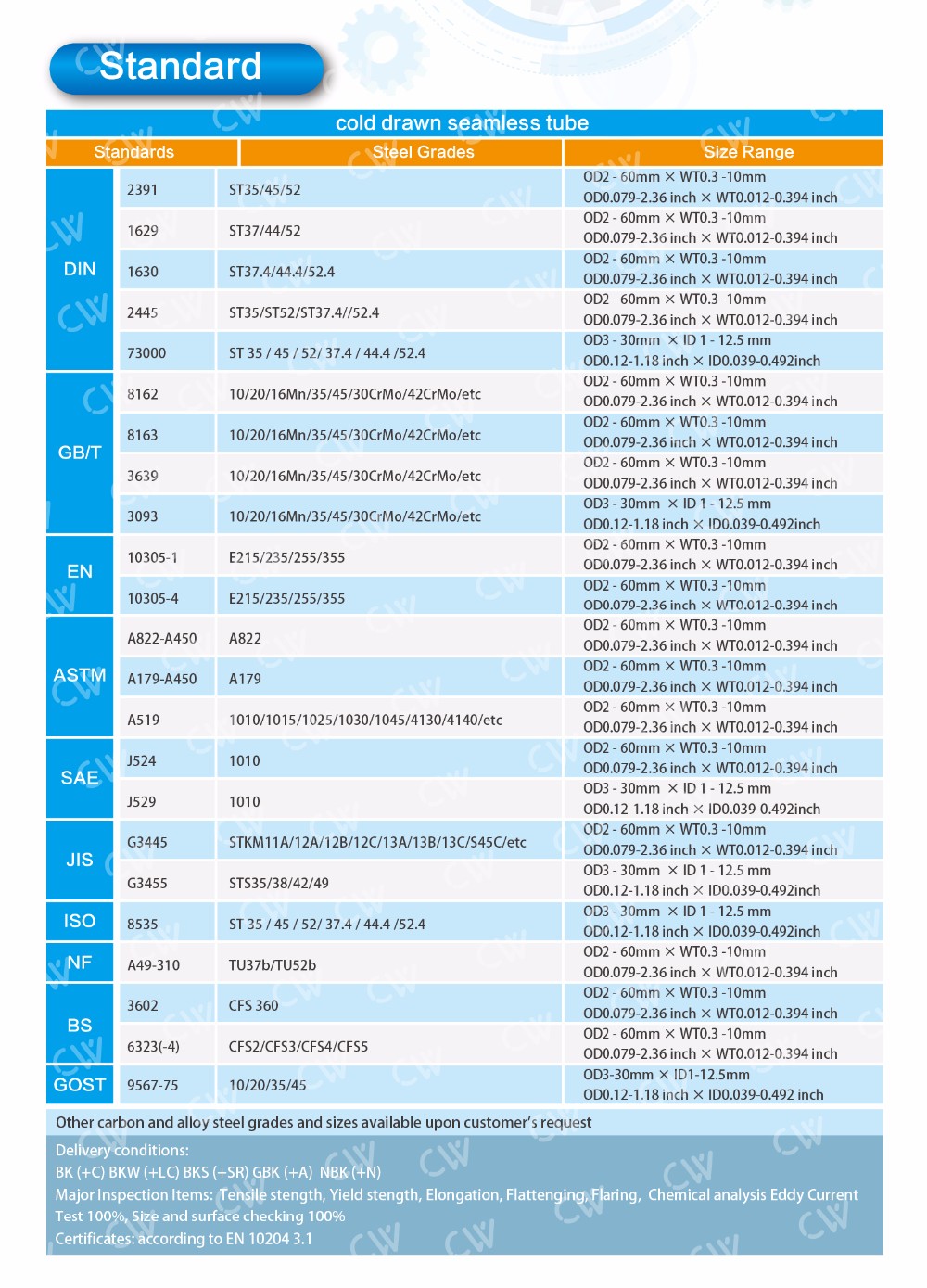

Product Name: EN 10305-4 E235 E355 (+)N Hydraulic Black Phosphate Line Seamless Pipe

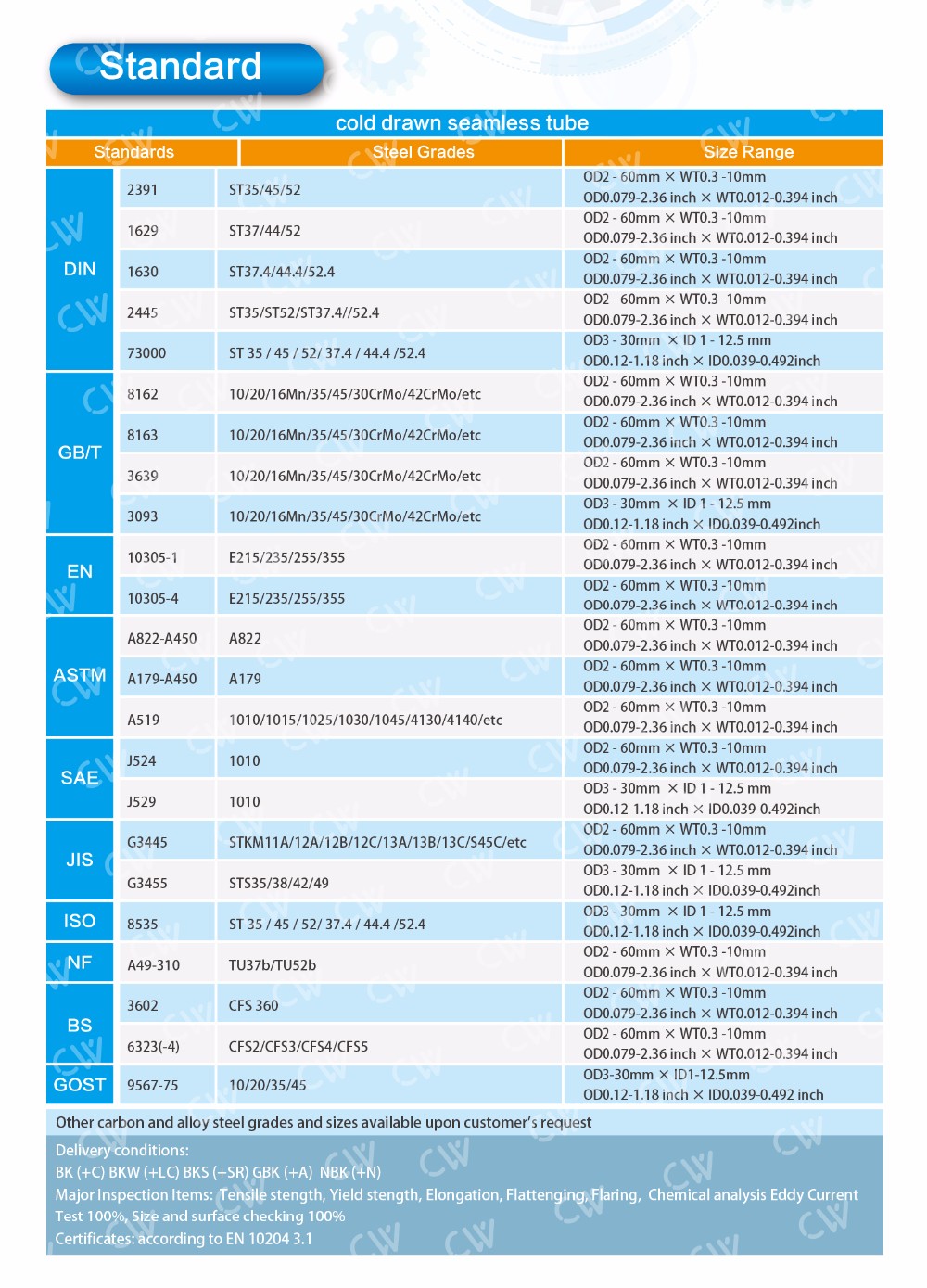

Manufacturing Standard: Compliant with EN 10305-4

Steel Grades: E235, E355 (+)N

Surface Treatment: Black Phosphate Coating

Production Method: Seamless Process

Hydraulic steel tube | |||||

Standard | Material | Delivery | Surface | Sizes | |

ASTM | A822-A450 | A822 | 1) BA 2)Black phosphating 3) Galvanizing Zinc Layer thickness more than 8um |

OD0.079-2.36 inch ×WT0.012-0.394inch | |

SAE | J524 | 1008-1015 | |||

Other steel grades also available upon request | |||||

Hydraulic steel tube | |||||

Standard | Material | Delivery | Surface | Sizes | |

DIN | 2391/1630/2445 | ST37.4 ST52.4 | NBK | 1) BA 2)Black phosphating 3) Galvanizing | OD2 -60mm × WT0.3 -10mm |

EN | 10305-4 | E235 E355 | (+)N | ||

BS | 3602 | CFS 360 | Zinc Layer thickness more than 8um | ||

Other steel grades also available upon request | |||||

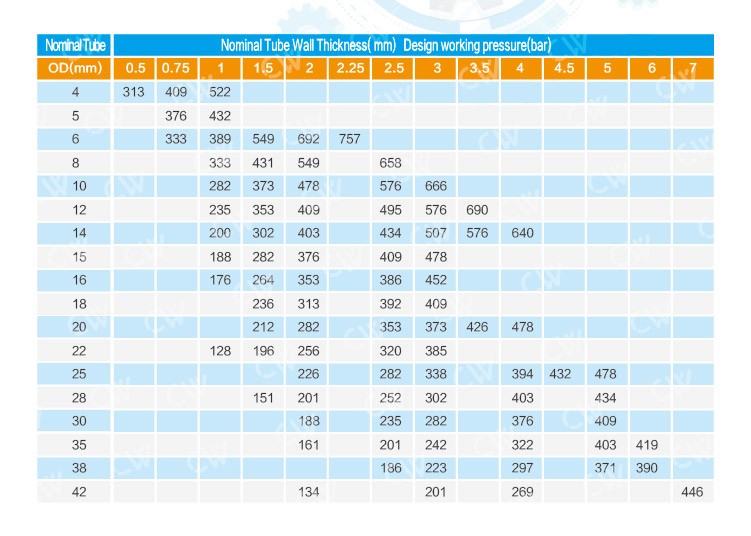

SIZE TOLERANCE | |||||

NAME |

Scope (mm) |

GB Series (mm) |

DIN series (mm) | Enterprise internal control standards (mm) |

Special high-precision (mm) |

Out diameter

| 2-30 | ±0.10 | ±0.08 | ±0.05 | ±0.03 |

31-40 | ±0.15 | ±0.15 | ±0.05 | ±0.03 | |

41-50 | ±0.20 | ±0.20 | ±0.08 | ±0.03 | |

51-60 | ±0.25 | ±0.25 | ±0.08 | ±0.03 | |

Wall thickness | 0.3-10 | ±10%; MIN±0.15 | ±10% | ±10%; MIN±0.05 | ±10%; MIN±0.03 |

Material selection: Select high-quality E235 or E355 steel.

Perforation: The tube is formed by hot or cold perforation process.

Cold rolling/cold drawing: Further reduce the outside diameter and wall thickness to achieve the desired dimensional accuracy.

Phosphating treatment: Black phosphating treatment on the surface to enhance corrosion resistance and wear resistance.

Quality testing: Rigorous non-destructive testing, such as eddy current testing, hydrostatic testing and dimensional testing.

High Precision: Conforms to industrial standards ensuring precise dimensions and geometric accuracy.

High-Quality Material: Made from high-grade E235 and E355 (+)N steel for excellent mechanical properties and durability.

Wide Application: Suitable for hydraulic systems, mechanical engineering, and other high-precision applications.

Surface Coating: Black phosphate coating enhances corrosion resistance and reduces friction losses.

Customizable: Available in various sizes and lengths to meet customer specifications.

Pipelines and tubing for hydraulic systems and equipment.

High-precision transmission components in mechanical engineering.

Hydraulic and transmission systems in the automotive industry.

E235 E355 hydraulic system Black phosphating seamless tube is specially designed for hydraulic system high pressure transmission line, made of high quality carbon steel or low alloy steel. This seamless pipe through high-quality phosphating process, improve the corrosion resistance and wear resistance of the pipe body, to ensure the long-term stable operation of the hydraulic system.

EN 10305-4 E235 E355 (+)N hydraulic black phosphate line seamless pipe manufacturer

Product Name: EN 10305-4 E235 E355 (+)N Hydraulic Black Phosphate Line Seamless Pipe

Manufacturing Standard: Compliant with EN 10305-4

Steel Grades: E235, E355 (+)N

Surface Treatment: Black Phosphate Coating

Production Method: Seamless Process

Hydraulic steel tube | |||||

Standard | Material | Delivery | Surface | Sizes | |

ASTM | A822-A450 | A822 | 1) BA 2)Black phosphating 3) Galvanizing Zinc Layer thickness more than 8um |

OD0.079-2.36 inch ×WT0.012-0.394inch | |

SAE | J524 | 1008-1015 | |||

Other steel grades also available upon request | |||||

Hydraulic steel tube | |||||

Standard | Material | Delivery | Surface | Sizes | |

DIN | 2391/1630/2445 | ST37.4 ST52.4 | NBK | 1) BA 2)Black phosphating 3) Galvanizing | OD2 -60mm × WT0.3 -10mm |

EN | 10305-4 | E235 E355 | (+)N | ||

BS | 3602 | CFS 360 | Zinc Layer thickness more than 8um | ||

Other steel grades also available upon request | |||||

SIZE TOLERANCE | |||||

NAME |

Scope (mm) |

GB Series (mm) |

DIN series (mm) | Enterprise internal control standards (mm) |

Special high-precision (mm) |

Out diameter

| 2-30 | ±0.10 | ±0.08 | ±0.05 | ±0.03 |

31-40 | ±0.15 | ±0.15 | ±0.05 | ±0.03 | |

41-50 | ±0.20 | ±0.20 | ±0.08 | ±0.03 | |

51-60 | ±0.25 | ±0.25 | ±0.08 | ±0.03 | |

Wall thickness | 0.3-10 | ±10%; MIN±0.15 | ±10% | ±10%; MIN±0.05 | ±10%; MIN±0.03 |

Material selection: Select high-quality E235 or E355 steel.

Perforation: The tube is formed by hot or cold perforation process.

Cold rolling/cold drawing: Further reduce the outside diameter and wall thickness to achieve the desired dimensional accuracy.

Phosphating treatment: Black phosphating treatment on the surface to enhance corrosion resistance and wear resistance.

Quality testing: Rigorous non-destructive testing, such as eddy current testing, hydrostatic testing and dimensional testing.

High Precision: Conforms to industrial standards ensuring precise dimensions and geometric accuracy.

High-Quality Material: Made from high-grade E235 and E355 (+)N steel for excellent mechanical properties and durability.

Wide Application: Suitable for hydraulic systems, mechanical engineering, and other high-precision applications.

Surface Coating: Black phosphate coating enhances corrosion resistance and reduces friction losses.

Customizable: Available in various sizes and lengths to meet customer specifications.

Pipelines and tubing for hydraulic systems and equipment.

High-precision transmission components in mechanical engineering.

Hydraulic and transmission systems in the automotive industry.

E235 E355 hydraulic system Black phosphating seamless tube is specially designed for hydraulic system high pressure transmission line, made of high quality carbon steel or low alloy steel. This seamless pipe through high-quality phosphating process, improve the corrosion resistance and wear resistance of the pipe body, to ensure the long-term stable operation of the hydraulic system.