T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon Steel

GB/T 8162 as per request

10 20 16Mn as per request

| Availability: | |

|---|---|

| Quantity: | |

GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe

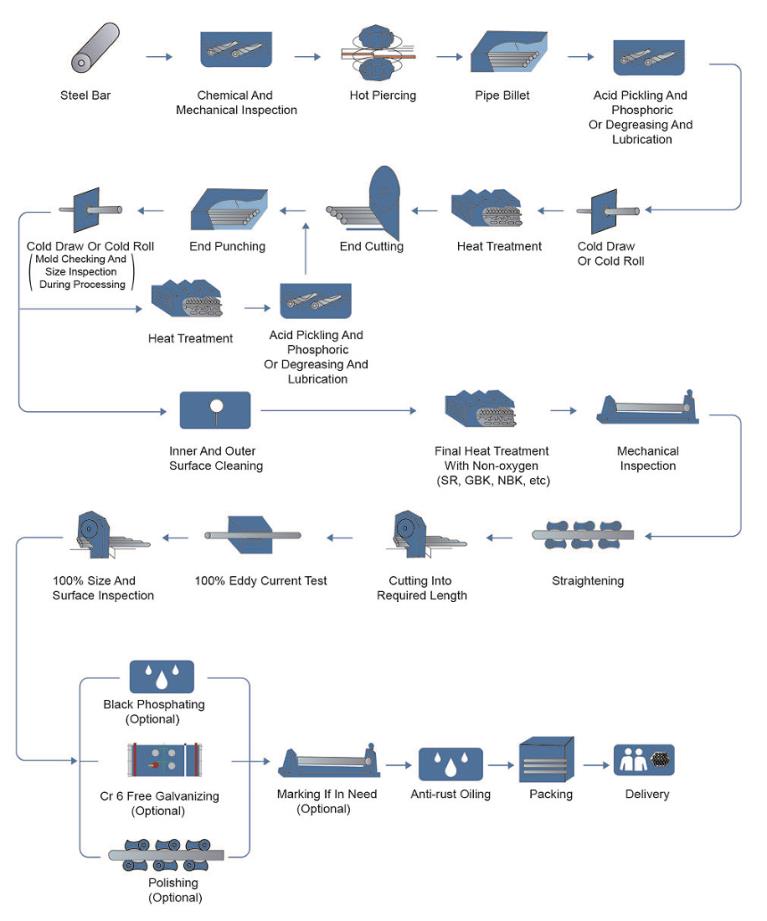

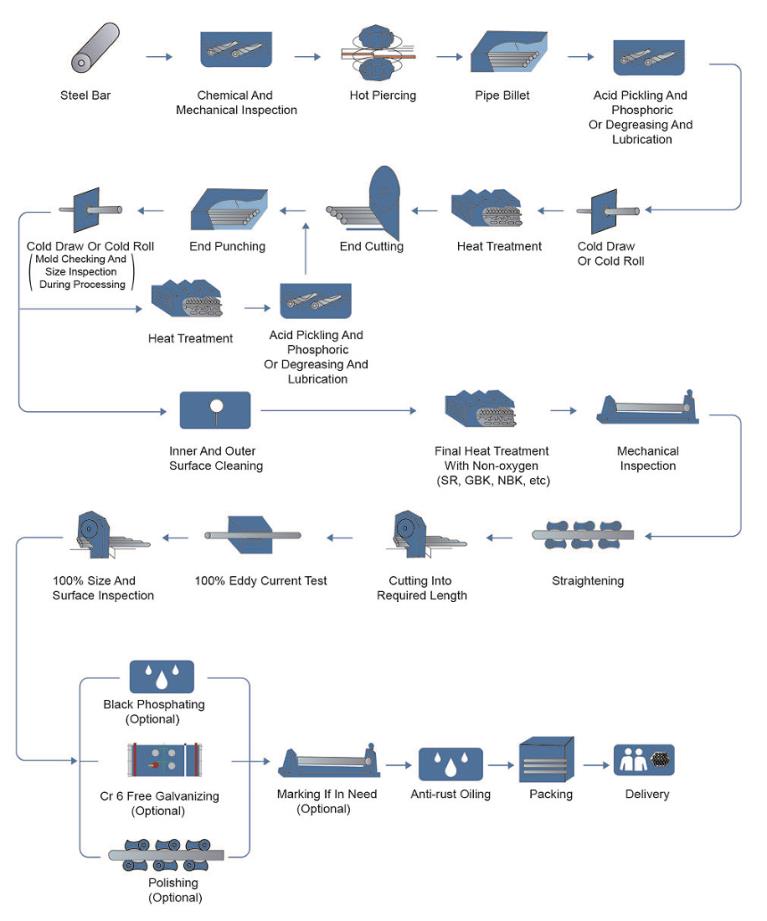

Detailed Image:

Description:

GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe is a steel pipe material with high strength, good corrosion resistance and good rust resistance. This steel pipe is produced in accordance with the Chinese national standard GB/T 8162, and has been treated by cold drawing process, which has excellent structural design and excellent performance characteristics. It has very good accuracy in diameter and length, but also has very good surface quality and internal structure. This steel pipe material is mainly used in industry, energy, transportation and other fields.

GB/T8162 seamless steel pipe

| Standard | Steel grade | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) |

| GB/T8162 | 10 | ≥ 335 | ≥ 205 | ≥ 24 |

| 20 | ≥ 390 | ≥ 245 | ≥ 20 | |

| 35 | ≥ 510 | ≥ 305 | ≥ 17 | |

| 45 | ≥ 590 | ≥ 335 | ≥ 14 | |

| 16Mn | ≥ 490 | ≥ 325 | ≥ 21 | |

| 12CrMo | ≥ 410 | ≥ 265 | ≥ 24 | |

| 15CrMo | ≥ 440 | ≥ 295 | ≥ 22 | |

| 12Cr1MoV | ≥ 490 | ≥ 245 | ≥ 22 |

| Standard | Steel grade | Chemical composition | |||||||

| C | Si | Mn | P、S | Cu | Ni | Mo | Cr | ||

| GB/T8162 | 10 | 0.07~0.14 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.15 |

| 20 | 0.17~0.24 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 35 | 0.32~0.40 | 0.17~0.37 | 0.50~0.80 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 45 | 0.42~0.50 | 0.17~0.37 | 0.50~0.80 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 16Mn | 0.12~0.20 | 0.20~0.55 | 1.20~1.60 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 12CrMo | 0.08~0.15 | 0.17~0.37 | 0.40~0.70 | ≤0.035 | ≤0.25 | ≤0.30 | 0.40~0.55 | 0.40~0.70 | |

| 15CrMo | 0.12~0.18 | 0.17~0.37 | 0.40~0.70 | ≤0.035 | ≤0.25 | ≤0.30 | 0.40~0.55 | 0.80~1.10 | |

| 12Cr1MoV | 0.08~0.15 | 0.17~0.37 | 0.40~0.70 | ≤0.035 | ≤0.25 | ≤0.30 | 0.25~0.35 | 0.90~1.20 | |

Features:

Seamless structure: This steel pipe adopts a seamless design, with smooth inner and outer walls and no oxide layer, which effectively prevents the retention and corrosion of the medium in the pipeline and ensures the safe operation of the pipeline.

High-quality materials: 10, 20, 16Mn and other high-quality carbon steels and low-alloy high-strength structural steels are selected as raw materials to ensure the high strength, high toughness and excellent mechanical properties of the steel pipe.

High precision: The cold drawing process makes the dimensional accuracy of the steel pipe higher, which can meet the needs of various precision engineering.

Corrosion resistance: The surface of the steel pipe has been specially treated, which has good corrosion resistance and can be used for a long time in harsh environments.

Application:

Mechanical Engineering:

In machinery manufacturing, GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe is often used to manufacture a variety of high-precision, high-strength parts, such as bearings, cylinders, cylinders, etc. Its high precision and excellent mechanical properties ensure the accuracy and durability of the components.

In automobile manufacturing, the steel pipe is widely used in key parts such as automobile chassis, suspension system, and transmission system to provide stable and reliable structural support for automobiles.

Petrochemical industry:

The petrochemical industry has extremely strict requirements for pipeline materials, which need to withstand high temperatures, high pressures and corrosive media. GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe has excellent corrosion resistance and high temperature resistance, making it the preferred material for transmission pipelines in the petrochemical industry.

Whether it's oil extraction, refining, chemical production, or oil storage and transportation, the tube provides a safe and reliable conveying solution.

Energy Engineering:

In power and heat engineering, GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe is commonly used in the manufacture of boilers, steam pipes, heat exchangers and other equipment. Its high strength and high temperature resistance ensure the safe operation of the equipment in high temperature and high pressure environments.

In the field of high-end energy such as nuclear power plants, the excellent performance of the steel pipe has also been widely used.

Architectural Engineering Field:

In construction projects, GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe is often used to build structures, make frames, etc. Its high strength and durability ensure the stability and safety of the building structure.

In addition, the steel pipe can also be used to make supporting structures for bridges, tunnels and other transportation facilities, providing strong support for transportation construction.

Other areas:

In addition to the above fields, GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe is also widely used in shipbuilding, aerospace, marine engineering and other fields. Its excellent performance and wide range of applications make the steel pipe an indispensable and important material in modern industry.

Company Information:

GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe

Detailed Image:

Description:

GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe is a steel pipe material with high strength, good corrosion resistance and good rust resistance. This steel pipe is produced in accordance with the Chinese national standard GB/T 8162, and has been treated by cold drawing process, which has excellent structural design and excellent performance characteristics. It has very good accuracy in diameter and length, but also has very good surface quality and internal structure. This steel pipe material is mainly used in industry, energy, transportation and other fields.

GB/T8162 seamless steel pipe

| Standard | Steel grade | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) |

| GB/T8162 | 10 | ≥ 335 | ≥ 205 | ≥ 24 |

| 20 | ≥ 390 | ≥ 245 | ≥ 20 | |

| 35 | ≥ 510 | ≥ 305 | ≥ 17 | |

| 45 | ≥ 590 | ≥ 335 | ≥ 14 | |

| 16Mn | ≥ 490 | ≥ 325 | ≥ 21 | |

| 12CrMo | ≥ 410 | ≥ 265 | ≥ 24 | |

| 15CrMo | ≥ 440 | ≥ 295 | ≥ 22 | |

| 12Cr1MoV | ≥ 490 | ≥ 245 | ≥ 22 |

| Standard | Steel grade | Chemical composition | |||||||

| C | Si | Mn | P、S | Cu | Ni | Mo | Cr | ||

| GB/T8162 | 10 | 0.07~0.14 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.15 |

| 20 | 0.17~0.24 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 35 | 0.32~0.40 | 0.17~0.37 | 0.50~0.80 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 45 | 0.42~0.50 | 0.17~0.37 | 0.50~0.80 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 16Mn | 0.12~0.20 | 0.20~0.55 | 1.20~1.60 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 12CrMo | 0.08~0.15 | 0.17~0.37 | 0.40~0.70 | ≤0.035 | ≤0.25 | ≤0.30 | 0.40~0.55 | 0.40~0.70 | |

| 15CrMo | 0.12~0.18 | 0.17~0.37 | 0.40~0.70 | ≤0.035 | ≤0.25 | ≤0.30 | 0.40~0.55 | 0.80~1.10 | |

| 12Cr1MoV | 0.08~0.15 | 0.17~0.37 | 0.40~0.70 | ≤0.035 | ≤0.25 | ≤0.30 | 0.25~0.35 | 0.90~1.20 | |

Features:

Seamless structure: This steel pipe adopts a seamless design, with smooth inner and outer walls and no oxide layer, which effectively prevents the retention and corrosion of the medium in the pipeline and ensures the safe operation of the pipeline.

High-quality materials: 10, 20, 16Mn and other high-quality carbon steels and low-alloy high-strength structural steels are selected as raw materials to ensure the high strength, high toughness and excellent mechanical properties of the steel pipe.

High precision: The cold drawing process makes the dimensional accuracy of the steel pipe higher, which can meet the needs of various precision engineering.

Corrosion resistance: The surface of the steel pipe has been specially treated, which has good corrosion resistance and can be used for a long time in harsh environments.

Application:

Mechanical Engineering:

In machinery manufacturing, GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe is often used to manufacture a variety of high-precision, high-strength parts, such as bearings, cylinders, cylinders, etc. Its high precision and excellent mechanical properties ensure the accuracy and durability of the components.

In automobile manufacturing, the steel pipe is widely used in key parts such as automobile chassis, suspension system, and transmission system to provide stable and reliable structural support for automobiles.

Petrochemical industry:

The petrochemical industry has extremely strict requirements for pipeline materials, which need to withstand high temperatures, high pressures and corrosive media. GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe has excellent corrosion resistance and high temperature resistance, making it the preferred material for transmission pipelines in the petrochemical industry.

Whether it's oil extraction, refining, chemical production, or oil storage and transportation, the tube provides a safe and reliable conveying solution.

Energy Engineering:

In power and heat engineering, GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe is commonly used in the manufacture of boilers, steam pipes, heat exchangers and other equipment. Its high strength and high temperature resistance ensure the safe operation of the equipment in high temperature and high pressure environments.

In the field of high-end energy such as nuclear power plants, the excellent performance of the steel pipe has also been widely used.

Architectural Engineering Field:

In construction projects, GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe is often used to build structures, make frames, etc. Its high strength and durability ensure the stability and safety of the building structure.

In addition, the steel pipe can also be used to make supporting structures for bridges, tunnels and other transportation facilities, providing strong support for transportation construction.

Other areas:

In addition to the above fields, GB/T 8162 10 20 16Mn Cold Drawn Seamless Steel Pipe is also widely used in shipbuilding, aerospace, marine engineering and other fields. Its excellent performance and wide range of applications make the steel pipe an indispensable and important material in modern industry.

Company Information: