T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

alloy steel

as per request

as per request

| Availability: | |

|---|---|

| Quantity: | |

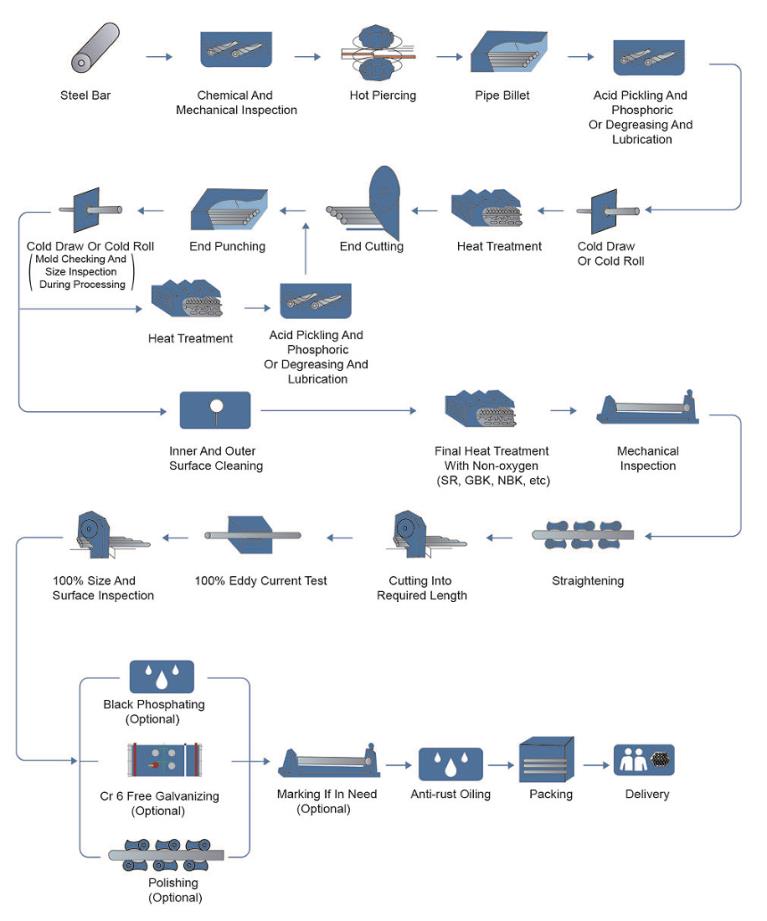

Detailed Image

Standard

| Material Chemical Composition(%) | ||||||||

| Standard | Steel Grade | C | Si | Mn | P | S | Cr | Mo |

| ASTM A519 | 4130/30CrMo | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.04 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| 4140/42CrMo | 0.38-0.43 | 0.15-0.35 | 0.75-1 | ≤0.04 | ≤0.04 | 0.8-1.1 | 0.15-0.25 | |

| Mechanical Performance | |||||||||

| CW | SR | A | N | ||||||

| RM Tensile Strength(Mpa)Min | A Elongation(%)Mn | RM Tensile Strength(Mpa)Min | A Elongation(%)Mn | RM Tensile Strength(Mpa)Min | Rel Yield Strength(Mpa)Min | A Elongation(%)Mn | RM Tensile Strength(Mpa)Min | Rel Yield Strength(Mpa)Min | A Elongation(%)Mn |

| - | - | 724 | 10 | 517 | 379 | 30 | 621 | 441 | 20 |

| - | - | 855 | 10 | 552 | 414 | 25 | 855 | 621 | 20 |

| Equivalent Material referance: | ||||||

| GB | TOCT | ASTM | BS | JIS | NF | DIN |

| 10F | 1010 | 040A10 | XC10 | |||

| 10 | 10 | 10,101,012 | 045M10 | S10C | XC10 | C10,CK10 |

| 20 | 20 | 1020 | 050A20 | S20C | XC18 | C22,CK22 |

| 45 | 45 | 1045 | 080M46 | S45C | XC45 | C45,CK45 |

| 30CrMo | 30XM | 4130 | 1717COS110 | SCM420 | 30CD4 | |

| 42CrMo | 4140 | 708A42 | 42CD4 | 42CrMo4 | ||

| 708M40 | ||||||

| 35CrMo | 35XM | 4135 | 708A37 | SCM3 | 35CD4 | 34CrMo4 |

Description

4130 Chromoly is often used when additional strength and tighter tolerances are needed. 4130 is great for sleeving and bending, making it ideal for fabricating structures where formability is key. The word Chromoly is derived from the combination of chromium and molybdenum, two of Chromoly’s main elements. It is an AISI 4130—Alloy steel grade 4130 metal.

Chromoly round tubing is typically used in automotive chassis, bicycle frames, crankshafts, and more. It is available for purchase by the foot up to 10’. Our 4130 round tubing features:

Sizes from .375” up to 4” OD.

Wall thicknesses from .032” up to .500”.

Non-standard random lengths from 17’ to 24’.

Industrial application for chromoly metal:

Chromoly is commonly found in airplane fuselages, bike frames, car roll cages, and other applications requiring a strong material with high durability. It is frequently used to create pipes used in situations with high temperatures. Chromoly is often more expensive to manufacture and process, reflecting the steel’s excellent performance capabilities.

Features of Chromoly Steel

The combination of chrome and molybdenum gives Chromoly a specific set of features. The additional chromium increases the strength (hardenability) and corrosion resistance in the metal material. The molybdenum makes the steel tougher. While Chromoly is easy to weld, it does require a few more considerations than standard steel or stainless steel metals due to the heightened strength of the material.

Advantages of Using Chromoly

Chromoly is a versatile steel grade alloy that can function in a variety of applications. It is malleable, resistant to scaling and oxidation, and produces a smooth and clean finish. Chrome moly metal produces an end-result with greater tensile strength when compared to other alloys.

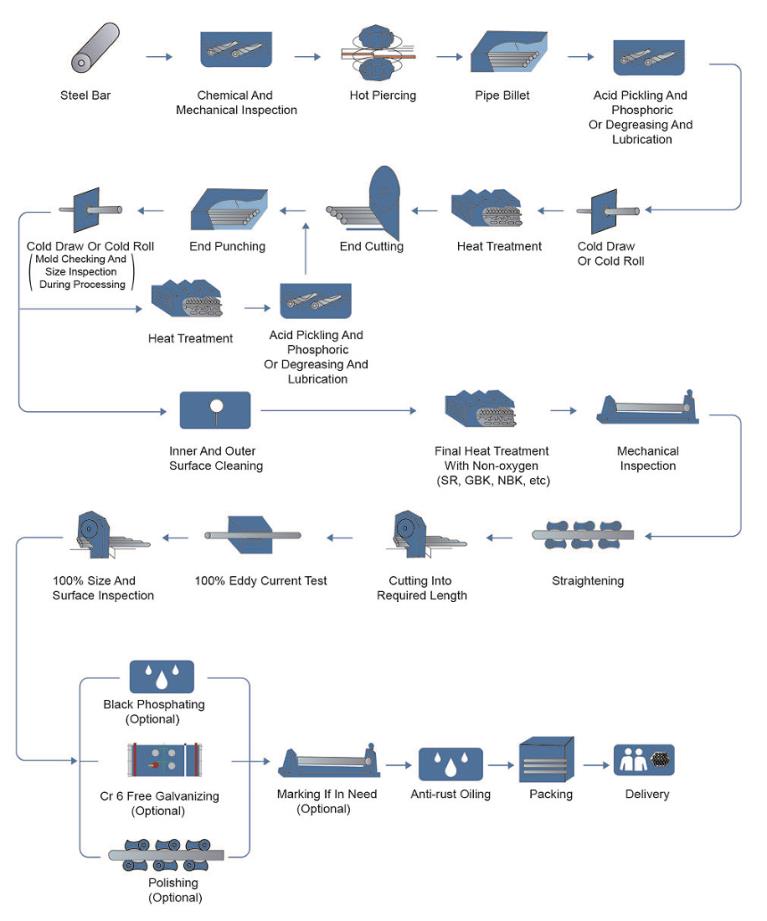

Detailed Image

Standard

| Material Chemical Composition(%) | ||||||||

| Standard | Steel Grade | C | Si | Mn | P | S | Cr | Mo |

| ASTM A519 | 4130/30CrMo | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.04 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| 4140/42CrMo | 0.38-0.43 | 0.15-0.35 | 0.75-1 | ≤0.04 | ≤0.04 | 0.8-1.1 | 0.15-0.25 | |

| Mechanical Performance | |||||||||

| CW | SR | A | N | ||||||

| RM Tensile Strength(Mpa)Min | A Elongation(%)Mn | RM Tensile Strength(Mpa)Min | A Elongation(%)Mn | RM Tensile Strength(Mpa)Min | Rel Yield Strength(Mpa)Min | A Elongation(%)Mn | RM Tensile Strength(Mpa)Min | Rel Yield Strength(Mpa)Min | A Elongation(%)Mn |

| - | - | 724 | 10 | 517 | 379 | 30 | 621 | 441 | 20 |

| - | - | 855 | 10 | 552 | 414 | 25 | 855 | 621 | 20 |

| Equivalent Material referance: | ||||||

| GB | TOCT | ASTM | BS | JIS | NF | DIN |

| 10F | 1010 | 040A10 | XC10 | |||

| 10 | 10 | 10,101,012 | 045M10 | S10C | XC10 | C10,CK10 |

| 20 | 20 | 1020 | 050A20 | S20C | XC18 | C22,CK22 |

| 45 | 45 | 1045 | 080M46 | S45C | XC45 | C45,CK45 |

| 30CrMo | 30XM | 4130 | 1717COS110 | SCM420 | 30CD4 | |

| 42CrMo | 4140 | 708A42 | 42CD4 | 42CrMo4 | ||

| 708M40 | ||||||

| 35CrMo | 35XM | 4135 | 708A37 | SCM3 | 35CD4 | 34CrMo4 |

Description

4130 Chromoly is often used when additional strength and tighter tolerances are needed. 4130 is great for sleeving and bending, making it ideal for fabricating structures where formability is key. The word Chromoly is derived from the combination of chromium and molybdenum, two of Chromoly’s main elements. It is an AISI 4130—Alloy steel grade 4130 metal.

Chromoly round tubing is typically used in automotive chassis, bicycle frames, crankshafts, and more. It is available for purchase by the foot up to 10’. Our 4130 round tubing features:

Sizes from .375” up to 4” OD.

Wall thicknesses from .032” up to .500”.

Non-standard random lengths from 17’ to 24’.

Industrial application for chromoly metal:

Chromoly is commonly found in airplane fuselages, bike frames, car roll cages, and other applications requiring a strong material with high durability. It is frequently used to create pipes used in situations with high temperatures. Chromoly is often more expensive to manufacture and process, reflecting the steel’s excellent performance capabilities.

Features of Chromoly Steel

The combination of chrome and molybdenum gives Chromoly a specific set of features. The additional chromium increases the strength (hardenability) and corrosion resistance in the metal material. The molybdenum makes the steel tougher. While Chromoly is easy to weld, it does require a few more considerations than standard steel or stainless steel metals due to the heightened strength of the material.

Advantages of Using Chromoly

Chromoly is a versatile steel grade alloy that can function in a variety of applications. It is malleable, resistant to scaling and oxidation, and produces a smooth and clean finish. Chrome moly metal produces an end-result with greater tensile strength when compared to other alloys.