T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon steel

as per request

as per request

| Availability: | |

|---|---|

| Quantity: | |

Detailed Image:

Standard:

Chemical Composition and Mechanical Performance:

Table 1- Chemical composition | ||||||

Steel Grade | C% | Si% | Mn% | P% | S% | AL% |

E215 | ≤0.10 | ≤0.05 | ≤0.7 | ≤0.025 | ≤0.025 | ≥0.025 |

E235 | ≤0.17 | ≤0.35 | 0.4-1.2 | ≤0.025 | ≤0.025 | |

E255 | ≤0.21 | ≤0.35 | 0.4-1.1 | ≤0.025 | ≤0.025 | |

E355 | ≤0.22 | ≤0.55 | ≤1.6 | ≤0.025 | ≤0.025 | |

Table 2 - Mechanical properties at room temperature | |||||||||

Delivery Condition | BK | BKW | GBK | NBK (N) | |||||

Steel Grade | Rm | A % | Rm | A % | Rm | A % | Rm | ReH | A % |

Mpa (Min) | (Min) | Mpa(Min) | (Min) | Mpa(Min) | (Min) | Mpa(Min) | Mpa(Min) | (Min) | |

E215 | 430 | 8 | 380 | 12 | 280 | 30 | 290~430 | 215 | 30 |

E235 | 480 | 6 | 420 | 10 | 315 | 25 | 340~480 | 235 | 25 |

E255 | 580 | 5 | 520 | 8 | 390 | 21 | 440~570 | 255 | 21 |

E355 | 640 | 4 | 580 | 7 | 450 | 22 | 490~630 | 355 | 22 |

Other Specification:

End Shape | Beveled end, plain end, vanished, or adding plastic caps to protect the two ends as per customer's requirements | |

Surface Treatment | Oiled, Galvanized, Phosphate etc | |

Technique | Cold drawn & cold rolled | |

Application | 1. Automotive and mechanical pipes | |

2. Petroleum cracking pipes | ||

3. High Pressure Boiler Pipe | ||

4. Low and middle pressure fluid transportation pipeline | ||

5. Chemical fertilizer equipment pipes | ||

6. Heat exchanger pipes | ||

Delivery Conditions | 1. BK (+C) | No heat treatment after last cold forming process. |

2. BKW (+LC) | After last heat treatment there is a light finishing pass (cold drawing) | |

3. BKS (+SR) | After the final cold forming process the tubes are stress relieve annealed. | |

4. GBK (+A) | After the final cold forming process the tubes are annealed in a controlled atmosphere. | |

5. NBK (+N) | After the final cold forming process the tubes are annealed above the upper transformation point in a controlled atmosphere. | |

Package | 1. Bundle Packing. | |

2. Plain end or vanished as per customer's request. | ||

3. Wrapped in waterproof paper. | ||

4. Sackcloth with several steel strips. | ||

5. Pack in heavy tri-wall boxes. | ||

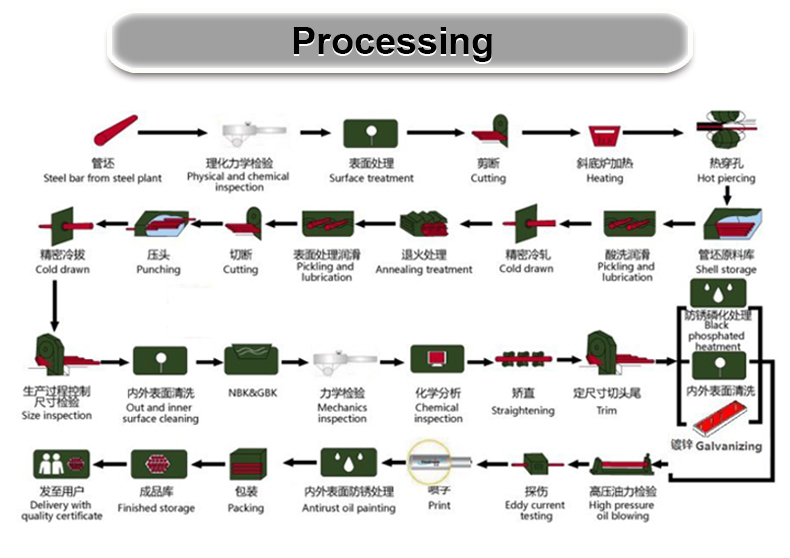

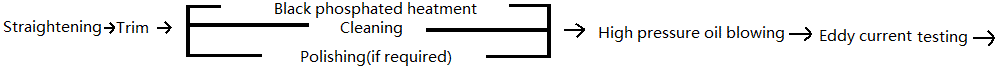

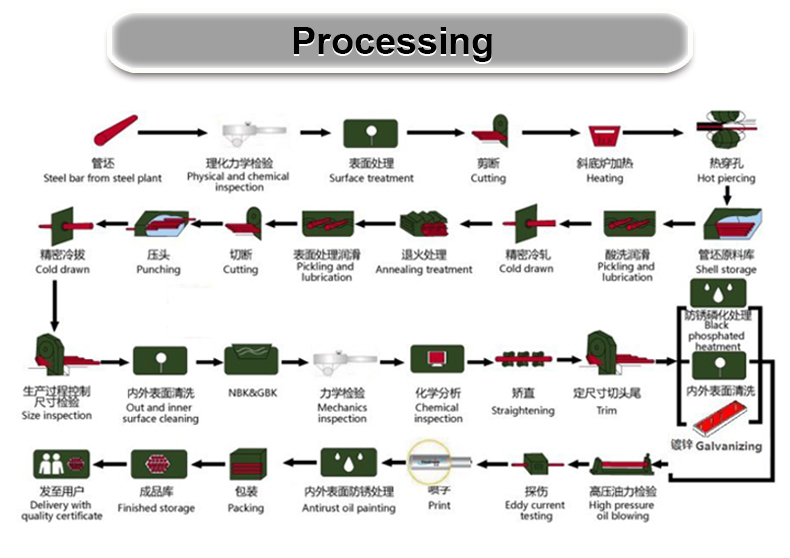

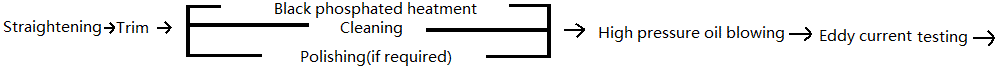

Steel bar from steel plant→Physical and chemical inspection→Surface treatment →Cutting → Heating→Hot piercing→Shell storage→Pickling and lubrication→Cold rolling→Heattreatmen →Pickling and lubrication→Cutting→Punching→Cold drawn→Size inspection→Outer and inner surface cleaning→NBK or GBK→Mechanics inspection→Chemical analysis

Antlrust oil palnting→print→packing→flnished storage→Dellivery with quality certificate

1.We adopt special techniques and special skill in the acid cleaning process to deal with the place where it's easy to form fold crevice;

2.Well organized process,especially annealing treatment in a severely technical manner;

3.In respect with lubrication,we adopt the international advanced level treating process in the world,and put the surface quality of our productsunder strict control in order to prevent causing surface crack.

Certificate:

Certificates:

According to EN 10204 3.1

Inspection Items:

Tensile stength, Yield stength, Elongation, Flattenging, FlaringChemical analysisEddy Current

Test 100%, Size and surface checking 100%Other test item can be arranged as per request

Company Information:

Detailed Image:

Standard:

Chemical Composition and Mechanical Performance:

Table 1- Chemical composition | ||||||

Steel Grade | C% | Si% | Mn% | P% | S% | AL% |

E215 | ≤0.10 | ≤0.05 | ≤0.7 | ≤0.025 | ≤0.025 | ≥0.025 |

E235 | ≤0.17 | ≤0.35 | 0.4-1.2 | ≤0.025 | ≤0.025 | |

E255 | ≤0.21 | ≤0.35 | 0.4-1.1 | ≤0.025 | ≤0.025 | |

E355 | ≤0.22 | ≤0.55 | ≤1.6 | ≤0.025 | ≤0.025 | |

Table 2 - Mechanical properties at room temperature | |||||||||

Delivery Condition | BK | BKW | GBK | NBK (N) | |||||

Steel Grade | Rm | A % | Rm | A % | Rm | A % | Rm | ReH | A % |

Mpa (Min) | (Min) | Mpa(Min) | (Min) | Mpa(Min) | (Min) | Mpa(Min) | Mpa(Min) | (Min) | |

E215 | 430 | 8 | 380 | 12 | 280 | 30 | 290~430 | 215 | 30 |

E235 | 480 | 6 | 420 | 10 | 315 | 25 | 340~480 | 235 | 25 |

E255 | 580 | 5 | 520 | 8 | 390 | 21 | 440~570 | 255 | 21 |

E355 | 640 | 4 | 580 | 7 | 450 | 22 | 490~630 | 355 | 22 |

Other Specification:

End Shape | Beveled end, plain end, vanished, or adding plastic caps to protect the two ends as per customer's requirements | |

Surface Treatment | Oiled, Galvanized, Phosphate etc | |

Technique | Cold drawn & cold rolled | |

Application | 1. Automotive and mechanical pipes | |

2. Petroleum cracking pipes | ||

3. High Pressure Boiler Pipe | ||

4. Low and middle pressure fluid transportation pipeline | ||

5. Chemical fertilizer equipment pipes | ||

6. Heat exchanger pipes | ||

Delivery Conditions | 1. BK (+C) | No heat treatment after last cold forming process. |

2. BKW (+LC) | After last heat treatment there is a light finishing pass (cold drawing) | |

3. BKS (+SR) | After the final cold forming process the tubes are stress relieve annealed. | |

4. GBK (+A) | After the final cold forming process the tubes are annealed in a controlled atmosphere. | |

5. NBK (+N) | After the final cold forming process the tubes are annealed above the upper transformation point in a controlled atmosphere. | |

Package | 1. Bundle Packing. | |

2. Plain end or vanished as per customer's request. | ||

3. Wrapped in waterproof paper. | ||

4. Sackcloth with several steel strips. | ||

5. Pack in heavy tri-wall boxes. | ||

Steel bar from steel plant→Physical and chemical inspection→Surface treatment →Cutting → Heating→Hot piercing→Shell storage→Pickling and lubrication→Cold rolling→Heattreatmen →Pickling and lubrication→Cutting→Punching→Cold drawn→Size inspection→Outer and inner surface cleaning→NBK or GBK→Mechanics inspection→Chemical analysis

Antlrust oil palnting→print→packing→flnished storage→Dellivery with quality certificate

1.We adopt special techniques and special skill in the acid cleaning process to deal with the place where it's easy to form fold crevice;

2.Well organized process,especially annealing treatment in a severely technical manner;

3.In respect with lubrication,we adopt the international advanced level treating process in the world,and put the surface quality of our productsunder strict control in order to prevent causing surface crack.

Certificate:

Certificates:

According to EN 10204 3.1

Inspection Items:

Tensile stength, Yield stength, Elongation, Flattenging, FlaringChemical analysisEddy Current

Test 100%, Size and surface checking 100%Other test item can be arranged as per request

Company Information: