T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon Steel

DIN2391

st37.4/52.4

| Availability: | |

|---|---|

| Quantity: | |

| Standard | Material | Delivery | Surface | Sizes | |

| DIN | 2391/1630/2445 | ST37.4 ST52.4 | NBK | 1) BA | OD2 -60mm × WT0.3 -10mm |

| EN | 10305-4 | E235, E355 | (+) N | 2) Black phosphated | |

| ASTM | A822-A450 | A822 | 3) Galvanizing | OD0.079-2.36 inch ×WT0.012-0.394inch | |

| SAE | J524 | 1010 | Silver; yellow; oilve green Galvanizing | ||

| BS | 3602 | CFS 360 | Layer thickness: min 8um | ||

| Other steel grades also available upon request | |||||

Product Description

Steel Pipes with high precision for Hydraulic Systems with Black Phosphating surface

Black Phosphated Hydraulic Tubes with High Precision and tight tolerance, the tubes are produced by precision cold drawn and cold rolling, then bright annealed in a protected atmosphere, afterwards it is blackphosphated on the surface

Production process:

DIN series tubes, cold drawn and bright annealed precision seamless steel tube is used as the tube to be phosphated. The phosphorization is realized with the imported chemical fluid to form a black film. The antirust oil is absorbed by means of the micropore on the film to prevent the tubes from getting rust.

Premium Carbon Steel Material: Manufactured from top-grade carbon steel, ensuring superior strength, toughness, and weldability for reliable performance in hydraulic fluid transmission systems.

Black Phosphate Coating: Coated with a black phosphate finish to enhance corrosion resistance, improve surface lubricity, and provide added protection against wear and abrasion.

Precision Manufacturing: Engineered with tight dimensional tolerances to ensure proper fit and compatibility with hydraulic fittings, connectors, and components, minimizing leakage and pressure loss.

Smooth Surface Finish: Finished to a smooth surface to reduce friction and flow resistance, facilitating smooth fluid flow and optimizing system performance.

Seamless Construction: Produced using seamless manufacturing processes to eliminate weld seams and potential weak points, ensuring structural integrity and reliability.

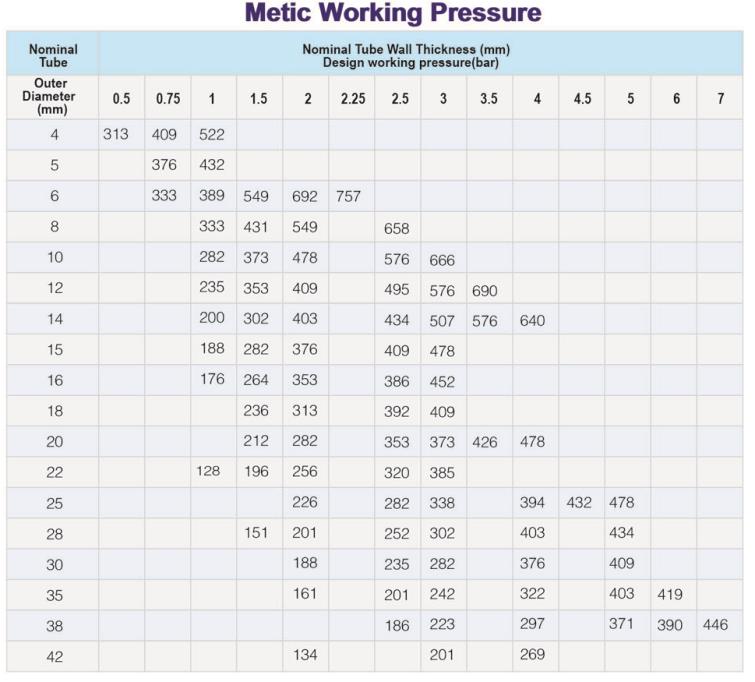

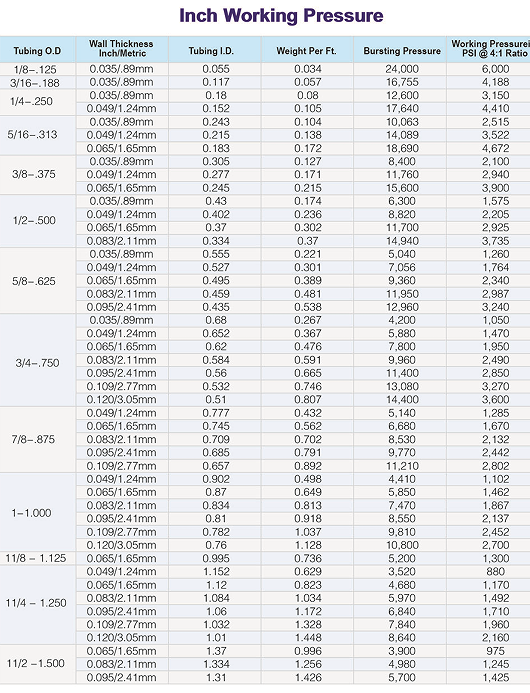

High Pressure Capability: Designed to withstand high hydraulic pressures encountered in industrial hydraulic systems, providing reliable performance and safety.

Wide Temperature Range: Capable of operating in a wide temperature range, making them suitable for use in both high-temperature and low-temperature hydraulic fluid transmission applications.

Versatile Applications: Suitable for various industrial hydraulic fluid transmission applications, including hydraulic power units, hydraulic machinery, hydraulic lifts, and hydraulic control systems.

Customizable Options: Available in a range of sizes, lengths, and configurations to meet the specific requirements of different hydraulic fluid transmission systems. Custom coatings and finishes can also be accommodated.

Hydraulic Power Units: Ideal for use in hydraulic power units and hydraulic pumps, providing reliable fluid transmission and power generation for industrial machinery and equipment.

Hydraulic Machinery: Used in various hydraulic machinery applications, including hydraulic presses, hydraulic cylinders, hydraulic motors, and hydraulic valves, ensuring efficient fluid transmission and control.

Hydraulic Lifts: Suitable for hydraulic lift systems, including vehicle lifts, material handling lifts, and hydraulic elevators, providing smooth and reliable lifting operations.

Hydraulic Control Systems: Employed in hydraulic control systems for industrial automation, process control, and machinery operation, ensuring precise fluid transmission and control.

| Standard | Material | Delivery | Surface | Sizes | |

| DIN | 2391/1630/2445 | ST37.4 ST52.4 | NBK | 1) BA | OD2 -60mm × WT0.3 -10mm |

| EN | 10305-4 | E235, E355 | (+) N | 2) Black phosphated | |

| ASTM | A822-A450 | A822 | 3) Galvanizing | OD0.079-2.36 inch ×WT0.012-0.394inch | |

| SAE | J524 | 1010 | Silver; yellow; oilve green Galvanizing | ||

| BS | 3602 | CFS 360 | Layer thickness: min 8um | ||

| Other steel grades also available upon request | |||||

Product Description

Steel Pipes with high precision for Hydraulic Systems with Black Phosphating surface

Black Phosphated Hydraulic Tubes with High Precision and tight tolerance, the tubes are produced by precision cold drawn and cold rolling, then bright annealed in a protected atmosphere, afterwards it is blackphosphated on the surface

Production process:

DIN series tubes, cold drawn and bright annealed precision seamless steel tube is used as the tube to be phosphated. The phosphorization is realized with the imported chemical fluid to form a black film. The antirust oil is absorbed by means of the micropore on the film to prevent the tubes from getting rust.

Premium Carbon Steel Material: Manufactured from top-grade carbon steel, ensuring superior strength, toughness, and weldability for reliable performance in hydraulic fluid transmission systems.

Black Phosphate Coating: Coated with a black phosphate finish to enhance corrosion resistance, improve surface lubricity, and provide added protection against wear and abrasion.

Precision Manufacturing: Engineered with tight dimensional tolerances to ensure proper fit and compatibility with hydraulic fittings, connectors, and components, minimizing leakage and pressure loss.

Smooth Surface Finish: Finished to a smooth surface to reduce friction and flow resistance, facilitating smooth fluid flow and optimizing system performance.

Seamless Construction: Produced using seamless manufacturing processes to eliminate weld seams and potential weak points, ensuring structural integrity and reliability.

High Pressure Capability: Designed to withstand high hydraulic pressures encountered in industrial hydraulic systems, providing reliable performance and safety.

Wide Temperature Range: Capable of operating in a wide temperature range, making them suitable for use in both high-temperature and low-temperature hydraulic fluid transmission applications.

Versatile Applications: Suitable for various industrial hydraulic fluid transmission applications, including hydraulic power units, hydraulic machinery, hydraulic lifts, and hydraulic control systems.

Customizable Options: Available in a range of sizes, lengths, and configurations to meet the specific requirements of different hydraulic fluid transmission systems. Custom coatings and finishes can also be accommodated.

Hydraulic Power Units: Ideal for use in hydraulic power units and hydraulic pumps, providing reliable fluid transmission and power generation for industrial machinery and equipment.

Hydraulic Machinery: Used in various hydraulic machinery applications, including hydraulic presses, hydraulic cylinders, hydraulic motors, and hydraulic valves, ensuring efficient fluid transmission and control.

Hydraulic Lifts: Suitable for hydraulic lift systems, including vehicle lifts, material handling lifts, and hydraulic elevators, providing smooth and reliable lifting operations.

Hydraulic Control Systems: Employed in hydraulic control systems for industrial automation, process control, and machinery operation, ensuring precise fluid transmission and control.