T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon ,alloy,stainless Steel

JIS G3445

STKM11A/12A/12B/12C/13A/13B/13C/S45C/etc

| Availability: | |

|---|---|

| Quantity: | |

| COLD DRAWN SEAMLESS STEEL TUBE | |||

| Standards | Steel Grades | Size Range | |

| DIN | 2391 | ST35/45/52 | OD2 - 60mm × WT0.3 -10mm |

| 1629 | ST37/44/52 | OD2 - 60mm × WT0.3 -10mm | |

| 1630 | ST37.4/44.4/52.4 | OD2 - 60mm × WT0.3 -10mm | |

| 2445 | ST35/ST52/ST37.4//52.4 | OD2 - 60mm × WT0.3 -10mm | |

| 73000 | ST 35 / 45 / 52/ 37.4 / 44.4 /52.4 | OD3 - 30mm × ID 1 - 12.5 mm | |

| GB/T | 8162 | 10/20/16Mn/35/45/30CrMo/42CrMo/etc | OD2 - 60mm × WT0.3 -10mm |

| 8163 | 10/20/16Mn/35/45/30CrMo/42CrMo/etc | OD2 - 60mm × WT0.3 -10mm | |

| 3639 | 10/20/16Mn/35/45/30CrMo/42CrMo/etc | OD2 - 60mm × WT0.3 -10mm | |

| 3093 | 10/20/16Mn/35/45/30CrMo/42CrMo/etc | OD3 - 30mm × ID 1 - 12.5 mm | |

| EN | 10305-1 | E215/235/255/355 | OD2 - 60mm × WT0.3 -10mm |

| 10305-4 | E215/235/255/355 | OD2 - 60mm × WT0.3 -10mm | |

| ASTM | A822-A450 | A822 | OD2 - 60mm × WT0.3 -10mm |

| A179-A450 | A179 | OD2 - 60mm × WT0.3 -10mm | |

| A519 | 1010/1015/1025/1030/1045/4130/4140/etc | OD2 - 60mm × WT0.3 -10mm | |

| SAE | J524 | Low carbon steel | OD2 - 60mm × WT0.3 -10mm |

| J529 | Low carbon steel | OD3 - 30mm × ID 1 - 12.5 mm | |

| JIS | G3445 | STKM11A/12A/12B/12C/13A/13B/13C/S45C/etc | OD2 - 60mm × WT0.3 -10mm |

| G3455 | STS35/38/42/49 | OD3 - 30mm × ID 1 - 12.5 mm | |

| ISO | 8535 | ST 35 / 45 / 52/ 37.4 / 44.4 /52.4 | OD3 - 30mm × ID 1 - 12.5 mm |

| NF | A49-310 | TU37b/TU52b | OD2 - 60mm × WT0.3 -10mm |

| BS | 3602 | CFS 360 | OD2 - 60mm × WT0.3 -10mm |

| 6323(-4) | CFS2/CFS3/CFS4/CFS5 | OD2 - 60mm × WT0.3 -10mm | |

| ASTM | A269 | 304,304L, 316, 316L | OD2 - 60mm × WT0.3 -10mm |

| EN | 10216-5 | 1.4401, 1.4404 | OD2 - 60mm × WT0.3 -10mm |

Description

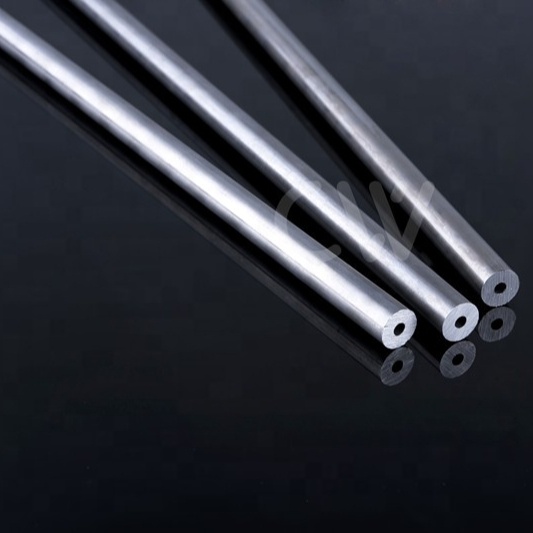

JIS G3445 Seamless Steel Pipe Description:

Overview:JIS G3445 is a Japanese Industrial Standard specifying seamless steel pipes used for machine structural purposes. These pipes are designed to meet high-dimensional accuracy and excellent surface quality requirements, making them suitable for various mechanical applications.

Material Composition:The seamless steel pipes under JIS G3445 are typically made from carbon steel or alloy steel, ensuring the necessary strength and durability for machine structural components.

Manufacturing Process:The manufacturing process involves precision engineering to meet the standard's specifications:

Material Selection: High-quality carbon or alloy steel is chosen for optimal performance.

Tube Formation: The steel is formed into seamless tubes using processes like piercing and elongation.

Heat Treatment: The tubes undergo heat treatment to achieve the desired mechanical properties.

Surface Finish: The pipes have a smooth surface finish, meeting the standard's stringent requirements.

Key Features:

Precision Dimensions: JIS G3445 seamless steel pipes adhere to precise dimensional tolerances, ensuring consistency and compatibility in machine structural applications.

High Strength: The use of quality steel and manufacturing processes results in seamless pipes with high tensile strength, suitable for handling mechanical loads.

Excellent Surface Quality: These pipes exhibit a smooth and clean surface finish, meeting the standard's expectations for visual inspection and overall quality.

Versatility: Designed for a variety of machine structural purposes, JIS G3445 seamless steel pipes find applications in automotive, machinery, and other mechanical engineering fields.

Types of Pipes under JIS G3445:

STKM 11A: Carbon steel pipes with low carbon content for general applications.

STKM 12A to STKM 13C: Carbon steel pipes with increased carbon content for enhanced strength and hardness.

STKM 14A: Carbon steel pipes with specified mechanical properties for precision components.

Applications:

JIS G3445 seamless steel pipes are widely used in:

Automotive components (chassis, suspension systems).

Machinery parts and components.

General engineering and structural applications.

Advantages:

Reliability: JIS G3445 seamless steel pipes are known for their reliability in machine structural applications.

Uniformity: Precise manufacturing processes ensure uniform dimensions and properties across the length of the pipe.

Conformance: Pipes under this standard conform to strict Japanese Industrial Standards, ensuring compliance with industry requirements.

In conclusion, JIS G3445 seamless steel pipes offer a reliable and precise solution for machine structural purposes, providing strength, durability, and consistent performance in various mechanical applications.

| COLD DRAWN SEAMLESS STEEL TUBE | |||

| Standards | Steel Grades | Size Range | |

| DIN | 2391 | ST35/45/52 | OD2 - 60mm × WT0.3 -10mm |

| 1629 | ST37/44/52 | OD2 - 60mm × WT0.3 -10mm | |

| 1630 | ST37.4/44.4/52.4 | OD2 - 60mm × WT0.3 -10mm | |

| 2445 | ST35/ST52/ST37.4//52.4 | OD2 - 60mm × WT0.3 -10mm | |

| 73000 | ST 35 / 45 / 52/ 37.4 / 44.4 /52.4 | OD3 - 30mm × ID 1 - 12.5 mm | |

| GB/T | 8162 | 10/20/16Mn/35/45/30CrMo/42CrMo/etc | OD2 - 60mm × WT0.3 -10mm |

| 8163 | 10/20/16Mn/35/45/30CrMo/42CrMo/etc | OD2 - 60mm × WT0.3 -10mm | |

| 3639 | 10/20/16Mn/35/45/30CrMo/42CrMo/etc | OD2 - 60mm × WT0.3 -10mm | |

| 3093 | 10/20/16Mn/35/45/30CrMo/42CrMo/etc | OD3 - 30mm × ID 1 - 12.5 mm | |

| EN | 10305-1 | E215/235/255/355 | OD2 - 60mm × WT0.3 -10mm |

| 10305-4 | E215/235/255/355 | OD2 - 60mm × WT0.3 -10mm | |

| ASTM | A822-A450 | A822 | OD2 - 60mm × WT0.3 -10mm |

| A179-A450 | A179 | OD2 - 60mm × WT0.3 -10mm | |

| A519 | 1010/1015/1025/1030/1045/4130/4140/etc | OD2 - 60mm × WT0.3 -10mm | |

| SAE | J524 | Low carbon steel | OD2 - 60mm × WT0.3 -10mm |

| J529 | Low carbon steel | OD3 - 30mm × ID 1 - 12.5 mm | |

| JIS | G3445 | STKM11A/12A/12B/12C/13A/13B/13C/S45C/etc | OD2 - 60mm × WT0.3 -10mm |

| G3455 | STS35/38/42/49 | OD3 - 30mm × ID 1 - 12.5 mm | |

| ISO | 8535 | ST 35 / 45 / 52/ 37.4 / 44.4 /52.4 | OD3 - 30mm × ID 1 - 12.5 mm |

| NF | A49-310 | TU37b/TU52b | OD2 - 60mm × WT0.3 -10mm |

| BS | 3602 | CFS 360 | OD2 - 60mm × WT0.3 -10mm |

| 6323(-4) | CFS2/CFS3/CFS4/CFS5 | OD2 - 60mm × WT0.3 -10mm | |

| ASTM | A269 | 304,304L, 316, 316L | OD2 - 60mm × WT0.3 -10mm |

| EN | 10216-5 | 1.4401, 1.4404 | OD2 - 60mm × WT0.3 -10mm |

Description

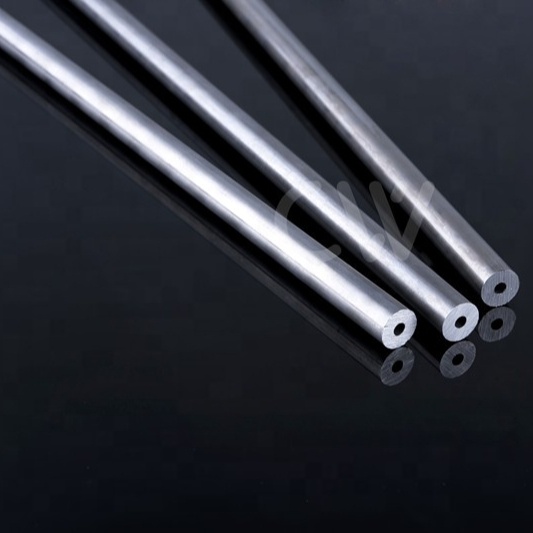

JIS G3445 Seamless Steel Pipe Description:

Overview:JIS G3445 is a Japanese Industrial Standard specifying seamless steel pipes used for machine structural purposes. These pipes are designed to meet high-dimensional accuracy and excellent surface quality requirements, making them suitable for various mechanical applications.

Material Composition:The seamless steel pipes under JIS G3445 are typically made from carbon steel or alloy steel, ensuring the necessary strength and durability for machine structural components.

Manufacturing Process:The manufacturing process involves precision engineering to meet the standard's specifications:

Material Selection: High-quality carbon or alloy steel is chosen for optimal performance.

Tube Formation: The steel is formed into seamless tubes using processes like piercing and elongation.

Heat Treatment: The tubes undergo heat treatment to achieve the desired mechanical properties.

Surface Finish: The pipes have a smooth surface finish, meeting the standard's stringent requirements.

Key Features:

Precision Dimensions: JIS G3445 seamless steel pipes adhere to precise dimensional tolerances, ensuring consistency and compatibility in machine structural applications.

High Strength: The use of quality steel and manufacturing processes results in seamless pipes with high tensile strength, suitable for handling mechanical loads.

Excellent Surface Quality: These pipes exhibit a smooth and clean surface finish, meeting the standard's expectations for visual inspection and overall quality.

Versatility: Designed for a variety of machine structural purposes, JIS G3445 seamless steel pipes find applications in automotive, machinery, and other mechanical engineering fields.

Types of Pipes under JIS G3445:

STKM 11A: Carbon steel pipes with low carbon content for general applications.

STKM 12A to STKM 13C: Carbon steel pipes with increased carbon content for enhanced strength and hardness.

STKM 14A: Carbon steel pipes with specified mechanical properties for precision components.

Applications:

JIS G3445 seamless steel pipes are widely used in:

Automotive components (chassis, suspension systems).

Machinery parts and components.

General engineering and structural applications.

Advantages:

Reliability: JIS G3445 seamless steel pipes are known for their reliability in machine structural applications.

Uniformity: Precise manufacturing processes ensure uniform dimensions and properties across the length of the pipe.

Conformance: Pipes under this standard conform to strict Japanese Industrial Standards, ensuring compliance with industry requirements.

In conclusion, JIS G3445 seamless steel pipes offer a reliable and precise solution for machine structural purposes, providing strength, durability, and consistent performance in various mechanical applications.