T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon Steel

as per request

as per request

| Availability: | |

|---|---|

| Quantity: | |

EN 10305-1 E355 OD 6mm cold drawn customized by automotive special section tube

SIZE TOLERANCE | |||||

NAME |

Scope (mm) |

GB Series (mm) |

DIN series (mm) | Enterprise internal control standards (mm) |

Special high-precision (mm) |

Out diameter

| 2-30 | ±0.10 | ±0.08 | ±0.05 | ±0.03 |

31-40 | ±0.15 | ±0.15 | ±0.05 | ±0.03 | |

41-50 | ±0.20 | ±0.20 | ±0.08 | ±0.03 | |

51-60 | ±0.25 | ±0.25 | ±0.08 | ±0.03 | |

Wall thickness | 0.3-10 | ±10%; MIN±0.15 | ±10% | ±10%; MIN±0.05 | ±10%; MIN±0.03 |

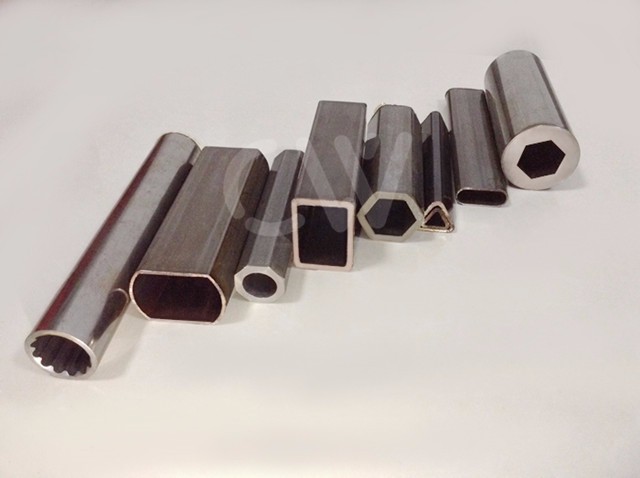

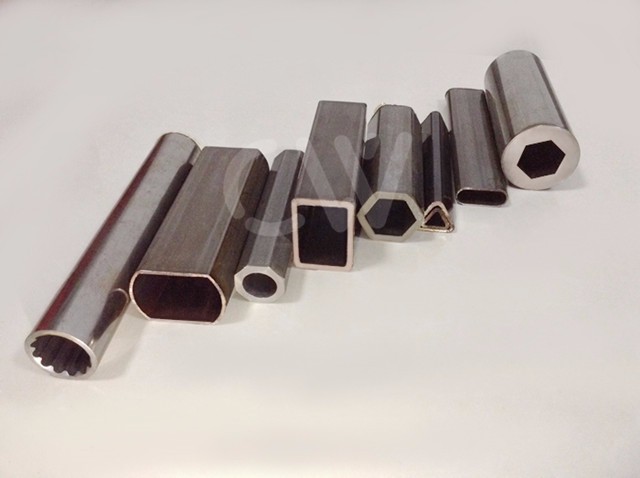

Cold drawn Seamless Special Section Tube

All Different Shapes Available Upon Request

(Example like Hexagonal,Oval, Octagonal, Cinquefoil and others)

Size, Shapes and steel grade as customers requests

| Some samples of related steel grade | ||||||

| GB | TOCT | ASTM | BS | JIS | NF | DIN |

| 10F | 1010 | 040A10 | XC10 | |||

| 10 | 10 | 10,101,012 | 045M10 | S10C | XC10 | C10,CK10 |

| 20 | 20 | 1020 | 050A20 | S20C | XC18 | C22,CK22 |

| 45 | 45 | 1045 | 080M46 | S45C | XC45 | C45,CK45 |

| 30CrMo | 30XM | 4130 | 1717COS110 | SCM420 | 30CD4 | |

| 42CrMo | 4140 | 708A42 | 42CD4 | 42CrMo4 | ||

| 708M40 | ||||||

| 35CrMo | 35XM | 4135 | 708A37 | SCM3 | 35CD4 | 34CrMo4 |

Cold drawing is a precision manufacturing process used to produce seamless steel tubes with enhanced dimensional accuracy and surface finish. The process involves pulling a solid steel rod through a die to reduce its diameter and achieve the desired dimensions. Cold drawing imparts favorable mechanical properties to the tubes, such as improved strength, toughness, and uniformity.

EN 10305-1 E355 tubes offer a range of customization options to meet diverse automotive requirements. These options include variations in dimensions, tolerances, surface finish, and additional treatments such as heat treatment or coating. Customization ensures tailored solutions that align with specific design criteria and performance standards.

The EN 10305-1 E355 tubes find widespread applications in various automotive components and systems. They are used in chassis structures, suspension systems, steering mechanisms, and exhaust systems, among others. Their high strength-to-weight ratio, dimensional accuracy, and corrosion resistance make them indispensable for ensuring vehicle performance, safety, and longevity.

EN 10305-1 E355 OD 6mm cold drawn customized by automotive special section tube

SIZE TOLERANCE | |||||

NAME |

Scope (mm) |

GB Series (mm) |

DIN series (mm) | Enterprise internal control standards (mm) |

Special high-precision (mm) |

Out diameter

| 2-30 | ±0.10 | ±0.08 | ±0.05 | ±0.03 |

31-40 | ±0.15 | ±0.15 | ±0.05 | ±0.03 | |

41-50 | ±0.20 | ±0.20 | ±0.08 | ±0.03 | |

51-60 | ±0.25 | ±0.25 | ±0.08 | ±0.03 | |

Wall thickness | 0.3-10 | ±10%; MIN±0.15 | ±10% | ±10%; MIN±0.05 | ±10%; MIN±0.03 |

Cold drawn Seamless Special Section Tube

All Different Shapes Available Upon Request

(Example like Hexagonal,Oval, Octagonal, Cinquefoil and others)

Size, Shapes and steel grade as customers requests

| Some samples of related steel grade | ||||||

| GB | TOCT | ASTM | BS | JIS | NF | DIN |

| 10F | 1010 | 040A10 | XC10 | |||

| 10 | 10 | 10,101,012 | 045M10 | S10C | XC10 | C10,CK10 |

| 20 | 20 | 1020 | 050A20 | S20C | XC18 | C22,CK22 |

| 45 | 45 | 1045 | 080M46 | S45C | XC45 | C45,CK45 |

| 30CrMo | 30XM | 4130 | 1717COS110 | SCM420 | 30CD4 | |

| 42CrMo | 4140 | 708A42 | 42CD4 | 42CrMo4 | ||

| 708M40 | ||||||

| 35CrMo | 35XM | 4135 | 708A37 | SCM3 | 35CD4 | 34CrMo4 |

Cold drawing is a precision manufacturing process used to produce seamless steel tubes with enhanced dimensional accuracy and surface finish. The process involves pulling a solid steel rod through a die to reduce its diameter and achieve the desired dimensions. Cold drawing imparts favorable mechanical properties to the tubes, such as improved strength, toughness, and uniformity.

EN 10305-1 E355 tubes offer a range of customization options to meet diverse automotive requirements. These options include variations in dimensions, tolerances, surface finish, and additional treatments such as heat treatment or coating. Customization ensures tailored solutions that align with specific design criteria and performance standards.

The EN 10305-1 E355 tubes find widespread applications in various automotive components and systems. They are used in chassis structures, suspension systems, steering mechanisms, and exhaust systems, among others. Their high strength-to-weight ratio, dimensional accuracy, and corrosion resistance make them indispensable for ensuring vehicle performance, safety, and longevity.