T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon Steel

DIN2445

st37.4/52.4

| Availability: | |

|---|---|

| Quantity: | |

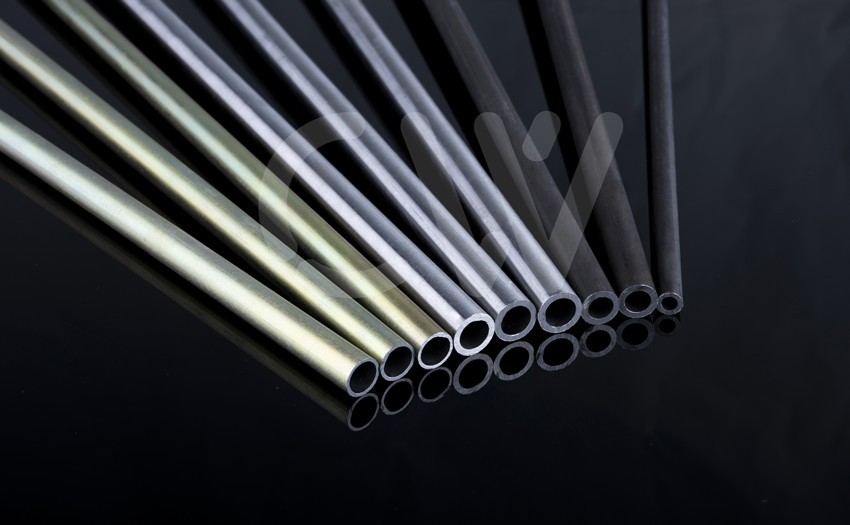

DIN 2445 ST37.4 OD 5mm hydraulic galvanized precision steel tube

Certificates: according to EN 10204 3.1

Inspection Items: Tensile stength, Yield stength, Elongation, Flattenging, Flaring

Chemical analysis

Eddy Current Test 100%, Size and surface checking 100%

Other test item can be arranged as per request

SIZE TOLERANCE | |||||

NAME |

Scope (mm) |

GB Series (mm) |

DIN series (mm) | Enterprise internal control standards (mm) |

Special high-precision (mm) |

Out diameter

| 2-30 | ±0.10 | ±0.08 | ±0.05 | ±0.03 |

31-40 | ±0.15 | ±0.15 | ±0.05 | ±0.03 | |

41-50 | ±0.20 | ±0.20 | ±0.08 | ±0.03 | |

51-60 | ±0.25 | ±0.25 | ±0.08 | ±0.03 | |

Wall thickness | 0.3-10 | ±10%; MIN±0.15 | ±10% | ±10%; MIN±0.05 | ±10%; MIN±0.03 |

Delivery Conditions

| Designaion | Symbol | Description |

| Cold drawn/hard | +C | No heat treatment after the final cold drawing process. |

| Cold drawn/soft | +LC | After the final heat treatment there is a suitable drawing pass. |

| Cold drawn and stress relieved | +SR | After the final cold drawing process there is a stress relief heat treatment in a controlled atmosphere. |

| Annealed | +A | After the final cold drawing process the tubes are annealed in a controlled atmosphere. |

| Normalized | +N | After the final cold drawing operation the tubes are normalized in a controlled atmosphere. |

Product Name: DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube

Product Description: The DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube is a high-quality, precision-engineered tube designed for hydraulic applications. This steel tube is manufactured according to the DIN 2445 standard and is galvanized to provide enhanced corrosion resistance. It is widely used in hydraulic systems where precision, durability, and resistance to corrosion are essential.

Material:

Grade: ST37.4 carbon steel

Chemical Composition: The steel tube is made from high-quality carbon steel, which typically includes elements such as carbon, manganese, silicon, phosphorus, and sulfur. This composition provides excellent strength, ductility, and weldability.

Features:

Precision Manufacturing: The DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube is manufactured with high precision to meet the stringent requirements of hydraulic systems. It has precise dimensions, tight tolerances, and a smooth internal surface, ensuring optimal flow characteristics and minimizing pressure drop.

Galvanized Coating: The steel tube is galvanized, which involves applying a protective zinc coating to the surface. This galvanized coating provides superior corrosion resistance, protecting the tube from rust, moisture, and other environmental factors. It extends the lifespan of the tube and ensures reliable performance in harsh operating conditions.

High Pressure Capability: This precision steel tube is designed to withstand high-pressure hydraulic applications. It has excellent structural integrity and strength, allowing it to handle the elevated pressures required for efficient fluid transmission. The tube's robust construction minimizes the risk of leaks or failures, ensuring reliable operation in hydraulic systems.

Wide Range of Applications: The DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube is suitable for various hydraulic applications, including hydraulic cylinders, hydraulic lines, hydraulic control systems, and other components. It is commonly used in industries such as automotive, construction, agriculture, and machinery, where precision and corrosion resistance are crucial.

Technical Specifications:

Outer Diameter: Customizable (commonly ranging from 4mm to 80mm)

Wall Thickness: Customizable (commonly ranging from 0.5mm to 10mm)

Length: Customizable

Tolerance: According to DIN 2445 standard or customer requirements

Surface Finish: Galvanized coating for enhanced corrosion resistance

Manufactured in compliance with DIN 2445 standards, ensuring adherence to strict quality and precision requirements.

Forged from high-grade ST37.4 steel, known for its excellent strength, formability, and suitability for hydraulic systems.

Features hydraulic galvanization for enhanced corrosion resistance, protecting the tube in challenging environmental conditions.

Engineered with precision tolerance to meet the demands of hydraulic applications, ensuring seamless integration and reliable operation.

Suitable for a wide range of hydraulic systems, including machinery, automotive components, and industrial equipment.

Designed for durability in dynamic conditions, providing a robust solution for hydraulic systems that require longevity and consistent performance.

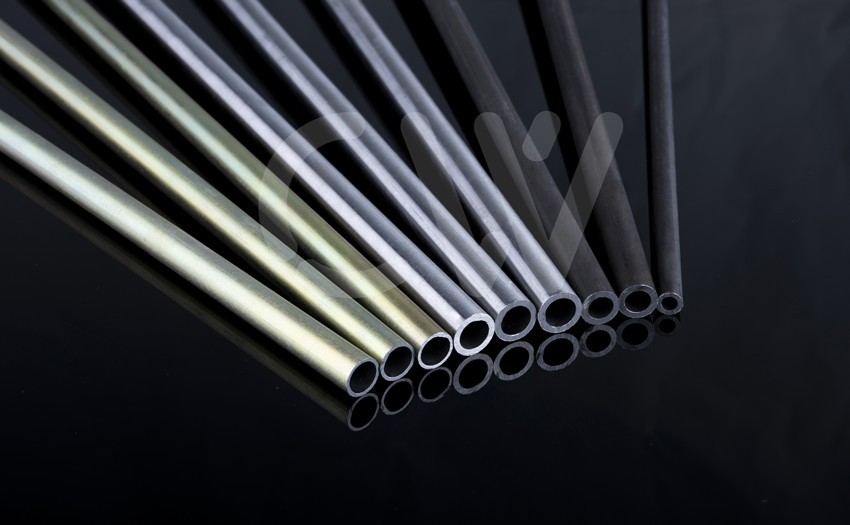

DIN 2445 ST37.4 OD 5mm hydraulic galvanized precision steel tube

Certificates: according to EN 10204 3.1

Inspection Items: Tensile stength, Yield stength, Elongation, Flattenging, Flaring

Chemical analysis

Eddy Current Test 100%, Size and surface checking 100%

Other test item can be arranged as per request

SIZE TOLERANCE | |||||

NAME |

Scope (mm) |

GB Series (mm) |

DIN series (mm) | Enterprise internal control standards (mm) |

Special high-precision (mm) |

Out diameter

| 2-30 | ±0.10 | ±0.08 | ±0.05 | ±0.03 |

31-40 | ±0.15 | ±0.15 | ±0.05 | ±0.03 | |

41-50 | ±0.20 | ±0.20 | ±0.08 | ±0.03 | |

51-60 | ±0.25 | ±0.25 | ±0.08 | ±0.03 | |

Wall thickness | 0.3-10 | ±10%; MIN±0.15 | ±10% | ±10%; MIN±0.05 | ±10%; MIN±0.03 |

Delivery Conditions

| Designaion | Symbol | Description |

| Cold drawn/hard | +C | No heat treatment after the final cold drawing process. |

| Cold drawn/soft | +LC | After the final heat treatment there is a suitable drawing pass. |

| Cold drawn and stress relieved | +SR | After the final cold drawing process there is a stress relief heat treatment in a controlled atmosphere. |

| Annealed | +A | After the final cold drawing process the tubes are annealed in a controlled atmosphere. |

| Normalized | +N | After the final cold drawing operation the tubes are normalized in a controlled atmosphere. |

Product Name: DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube

Product Description: The DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube is a high-quality, precision-engineered tube designed for hydraulic applications. This steel tube is manufactured according to the DIN 2445 standard and is galvanized to provide enhanced corrosion resistance. It is widely used in hydraulic systems where precision, durability, and resistance to corrosion are essential.

Material:

Grade: ST37.4 carbon steel

Chemical Composition: The steel tube is made from high-quality carbon steel, which typically includes elements such as carbon, manganese, silicon, phosphorus, and sulfur. This composition provides excellent strength, ductility, and weldability.

Features:

Precision Manufacturing: The DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube is manufactured with high precision to meet the stringent requirements of hydraulic systems. It has precise dimensions, tight tolerances, and a smooth internal surface, ensuring optimal flow characteristics and minimizing pressure drop.

Galvanized Coating: The steel tube is galvanized, which involves applying a protective zinc coating to the surface. This galvanized coating provides superior corrosion resistance, protecting the tube from rust, moisture, and other environmental factors. It extends the lifespan of the tube and ensures reliable performance in harsh operating conditions.

High Pressure Capability: This precision steel tube is designed to withstand high-pressure hydraulic applications. It has excellent structural integrity and strength, allowing it to handle the elevated pressures required for efficient fluid transmission. The tube's robust construction minimizes the risk of leaks or failures, ensuring reliable operation in hydraulic systems.

Wide Range of Applications: The DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube is suitable for various hydraulic applications, including hydraulic cylinders, hydraulic lines, hydraulic control systems, and other components. It is commonly used in industries such as automotive, construction, agriculture, and machinery, where precision and corrosion resistance are crucial.

Technical Specifications:

Outer Diameter: Customizable (commonly ranging from 4mm to 80mm)

Wall Thickness: Customizable (commonly ranging from 0.5mm to 10mm)

Length: Customizable

Tolerance: According to DIN 2445 standard or customer requirements

Surface Finish: Galvanized coating for enhanced corrosion resistance

Manufactured in compliance with DIN 2445 standards, ensuring adherence to strict quality and precision requirements.

Forged from high-grade ST37.4 steel, known for its excellent strength, formability, and suitability for hydraulic systems.

Features hydraulic galvanization for enhanced corrosion resistance, protecting the tube in challenging environmental conditions.

Engineered with precision tolerance to meet the demands of hydraulic applications, ensuring seamless integration and reliable operation.

Suitable for a wide range of hydraulic systems, including machinery, automotive components, and industrial equipment.

Designed for durability in dynamic conditions, providing a robust solution for hydraulic systems that require longevity and consistent performance.