T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon ,alloy,stainless Steel

EN10305-1

E215/235/255/355 as per request

| Availability: | |

|---|---|

| Quantity: | |

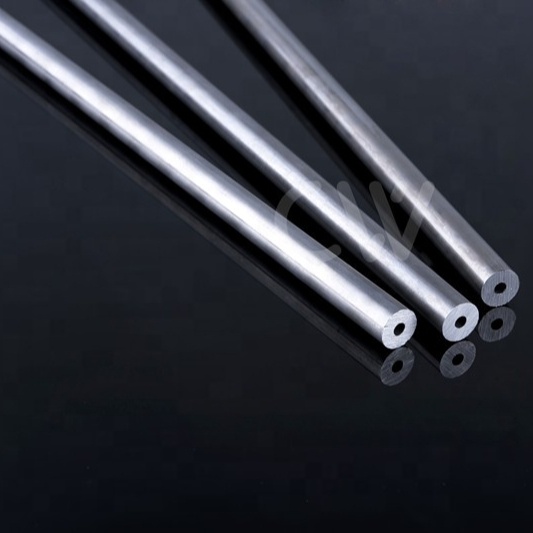

En10305-1 Cold Drawn Seamless Steel Tube/Pipe for Heat Exchanger

Details Images

Overview

The En10305-1 Cold Drawn Seamless Steel Tube/Pipe for Heat Exchanger stands as a cornerstone in heat exchanger technology, meticulously crafted to meet the exacting demands of heat transfer applications. Engineered through cold drawing processes, this seamless tube ensures superior dimensional accuracy, surface finish, and mechanical properties, making it an indispensable component in heat exchanger systems across various industries.

Cold Drawn Manufacturing: Crafted through cold drawing processes, ensuring precise dimensional tolerances, excellent surface finish, and enhanced mechanical properties critical for heat exchanger applications.

Seamless Design: Engineered with a seamless construction, eliminating weld seams and reducing the risk of corrosion and leakage, vital for maintaining operational integrity in high-pressure and high-temperature environments.

High Precision Tolerance: Manufactured to stringent dimensional tolerances as per En10305-1 standards, ensuring compatibility with standard heat exchanger components and facilitating seamless integration into existing systems.

Optimized Heat Transfer: Designed to facilitate efficient heat transfer, maximizing the thermal performance of heat exchanger systems and ensuring optimal energy utilization.

Wide Compatibility: Suitable for a wide range of heat exchanger applications, including HVAC systems, automotive radiators, industrial process heating, chemical processing, and more.

Standard: En10305-1

Material: Cold Drawn Seamless Steel

Construction: Seamless

Outer Diameter (OD): Customizable

Wall Thickness (WT): Customizable

Length: Customizable

Surface Finish: Bright Annealed or Pickled

HVAC Systems: Integrated into HVAC (Heating, Ventilation, and Air Conditioning) systems for efficient heat exchange between air streams, ensuring optimal indoor climate control and energy efficiency.

Automotive Radiators: Utilized in automotive radiators for the efficient transfer of heat from the engine coolant, maintaining optimal engine operating temperatures and prolonging engine life.

Industrial Process Heating: Employed in heat exchangers for industrial process heating applications, facilitating the precise control of temperature in manufacturing processes and chemical reactions.

Chemical Processing: Used in heat exchangers within the chemical industry for the controlled heating and cooling of chemical substances, ensuring product quality, and process efficiency.

Each En10305-1 Cold Drawn Seamless Steel Tube/Pipe for Heat Exchanger undergoes rigorous quality assurance procedures to ensure compliance with industry standards and customer specifications. Our quality control measures include dimensional inspection, surface finish evaluation, and mechanical testing, guaranteeing superior product quality and performance.

We offer customization options for the outer diameter, wall thickness, length, and surface finish of the cold drawn seamless steel tube to meet specific heat exchanger requirements. Our engineering team collaborates closely with customers to develop tailored solutions that optimize heat transfer efficiency and reliability.

The En10305-1 Cold Drawn Seamless Steel Tube/Pipe, tailored specifically for heat exchanger applications, embodies the pinnacle of heat transfer technology. It boasts unparalleled dimensional precision, impeccable surface quality, and superior mechanical attributes. The seamless nature of its construction, coupled with meticulous tolerances and broad industrial compatibility, renders it an indispensable element in heat exchanger systems spanning diverse sectors.

For more information or customization inquiries, please contact us.

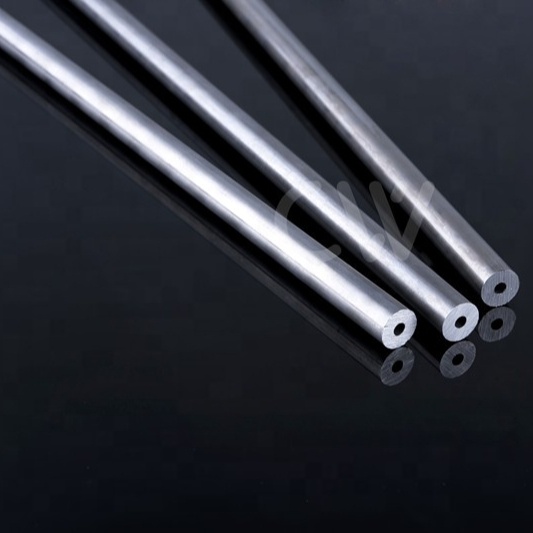

En10305-1 Cold Drawn Seamless Steel Tube/Pipe for Heat Exchanger

Details Images

Overview

The En10305-1 Cold Drawn Seamless Steel Tube/Pipe for Heat Exchanger stands as a cornerstone in heat exchanger technology, meticulously crafted to meet the exacting demands of heat transfer applications. Engineered through cold drawing processes, this seamless tube ensures superior dimensional accuracy, surface finish, and mechanical properties, making it an indispensable component in heat exchanger systems across various industries.

Cold Drawn Manufacturing: Crafted through cold drawing processes, ensuring precise dimensional tolerances, excellent surface finish, and enhanced mechanical properties critical for heat exchanger applications.

Seamless Design: Engineered with a seamless construction, eliminating weld seams and reducing the risk of corrosion and leakage, vital for maintaining operational integrity in high-pressure and high-temperature environments.

High Precision Tolerance: Manufactured to stringent dimensional tolerances as per En10305-1 standards, ensuring compatibility with standard heat exchanger components and facilitating seamless integration into existing systems.

Optimized Heat Transfer: Designed to facilitate efficient heat transfer, maximizing the thermal performance of heat exchanger systems and ensuring optimal energy utilization.

Wide Compatibility: Suitable for a wide range of heat exchanger applications, including HVAC systems, automotive radiators, industrial process heating, chemical processing, and more.

Standard: En10305-1

Material: Cold Drawn Seamless Steel

Construction: Seamless

Outer Diameter (OD): Customizable

Wall Thickness (WT): Customizable

Length: Customizable

Surface Finish: Bright Annealed or Pickled

HVAC Systems: Integrated into HVAC (Heating, Ventilation, and Air Conditioning) systems for efficient heat exchange between air streams, ensuring optimal indoor climate control and energy efficiency.

Automotive Radiators: Utilized in automotive radiators for the efficient transfer of heat from the engine coolant, maintaining optimal engine operating temperatures and prolonging engine life.

Industrial Process Heating: Employed in heat exchangers for industrial process heating applications, facilitating the precise control of temperature in manufacturing processes and chemical reactions.

Chemical Processing: Used in heat exchangers within the chemical industry for the controlled heating and cooling of chemical substances, ensuring product quality, and process efficiency.

Each En10305-1 Cold Drawn Seamless Steel Tube/Pipe for Heat Exchanger undergoes rigorous quality assurance procedures to ensure compliance with industry standards and customer specifications. Our quality control measures include dimensional inspection, surface finish evaluation, and mechanical testing, guaranteeing superior product quality and performance.

We offer customization options for the outer diameter, wall thickness, length, and surface finish of the cold drawn seamless steel tube to meet specific heat exchanger requirements. Our engineering team collaborates closely with customers to develop tailored solutions that optimize heat transfer efficiency and reliability.

The En10305-1 Cold Drawn Seamless Steel Tube/Pipe, tailored specifically for heat exchanger applications, embodies the pinnacle of heat transfer technology. It boasts unparalleled dimensional precision, impeccable surface quality, and superior mechanical attributes. The seamless nature of its construction, coupled with meticulous tolerances and broad industrial compatibility, renders it an indispensable element in heat exchanger systems spanning diverse sectors.

For more information or customization inquiries, please contact us.