T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon Steel

JIS G3445

SKTM 11A/12A/12B/12C/13A/13B/13C

| Availability: | |

|---|---|

| Quantity: | |

JIS G3445 STKM11A OD 4mm fuel injection seamless steel pipe

Certificates: according to EN 10204 3.1

Inspection Items: Tensile stength, Yield stength, Elongation, Flattenging, Flaring

Chemical analysis

Eddy Current Test 100%, Size and surface checking 100%

Other test item can be arranged as per request

| Steel Grade | Material Number | C Max | Si Max | Mn | P Max | S Max | Cr | Mo | Tensile strength Rm (Mpa) Min | Yield Strength Reh (Mpa) Min | A Elongation(%) Min | |

| JIS G3445 | STKM 11A | - | 0.12 | 0.35 | Max 0.60 | 0.04 | 0.04 | - | - | 290 | - | 35 |

| STKM 12A | - | 0.12 | 0.35 | Max 0.60 | 0.04 | 0.04 | - | - | 340 | 175 | 30 | |

| SKTM 12B | - | 0.12 | 0.35 | Max 0.60 | 0.04 | 0.04 | - | - | 390 | 275 | 25 | |

| SKTM 12C | - | 0.12 | 0.35 | Max 0.60 | 0.04 | 0.04 | - | - | 470 | 355 | 20 | |

| STKM 13A | - | 0.25 | 0.35 | 0.3-0.9 | 0.04 | 0.04 | - | - | 370 | 215 | 30 | |

| STKM 13B | - | 0.25 | 0.35 | 0.3-0.9 | 0.04 | 0.04 | - | - | 440 | 305 | 20 | |

| STKM 13C | - | 0.25 | 0.35 | 0.3-0.9 | 0.04 | 0.04 | - | - | 510 | 380 |

15 |

Description

Key Features

Compliance with JIS G3445 Standards: Designed and manufactured in accordance with JIS G3445 standards, this seamless steel pipe adheres to strict quality control measures, guaranteeing reliability and consistency in performance.

STKM11A Grade Material: Fabricated from STKM11A grade steel, this pipe exhibits superior strength, ductility, and weldability, making it an ideal choice for demanding fuel injection applications.

Seamless Construction: Utilizing seamless manufacturing techniques, the pipe boasts a smooth internal surface and uniform wall thickness, minimizing flow resistance and ensuring uninterrupted fuel flow for optimal engine performance.

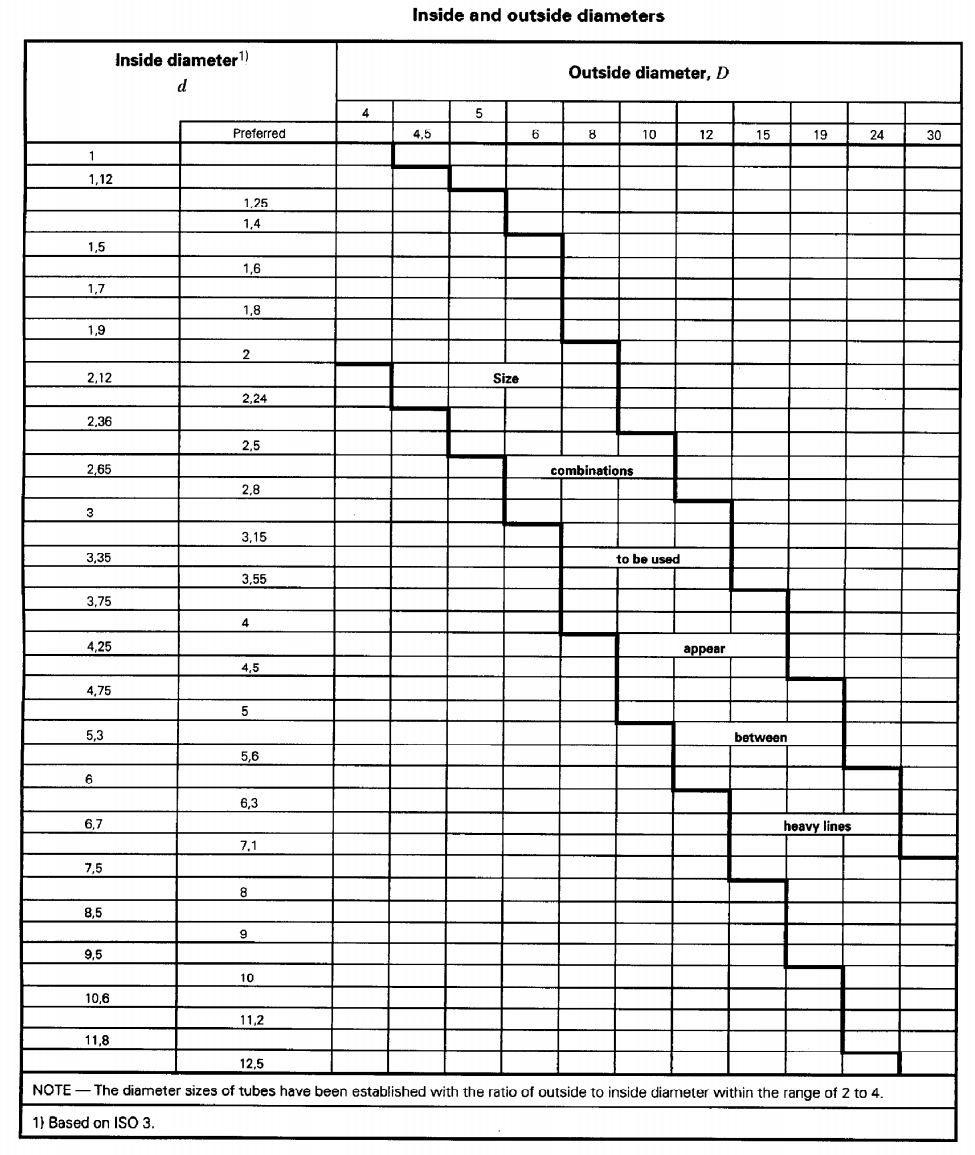

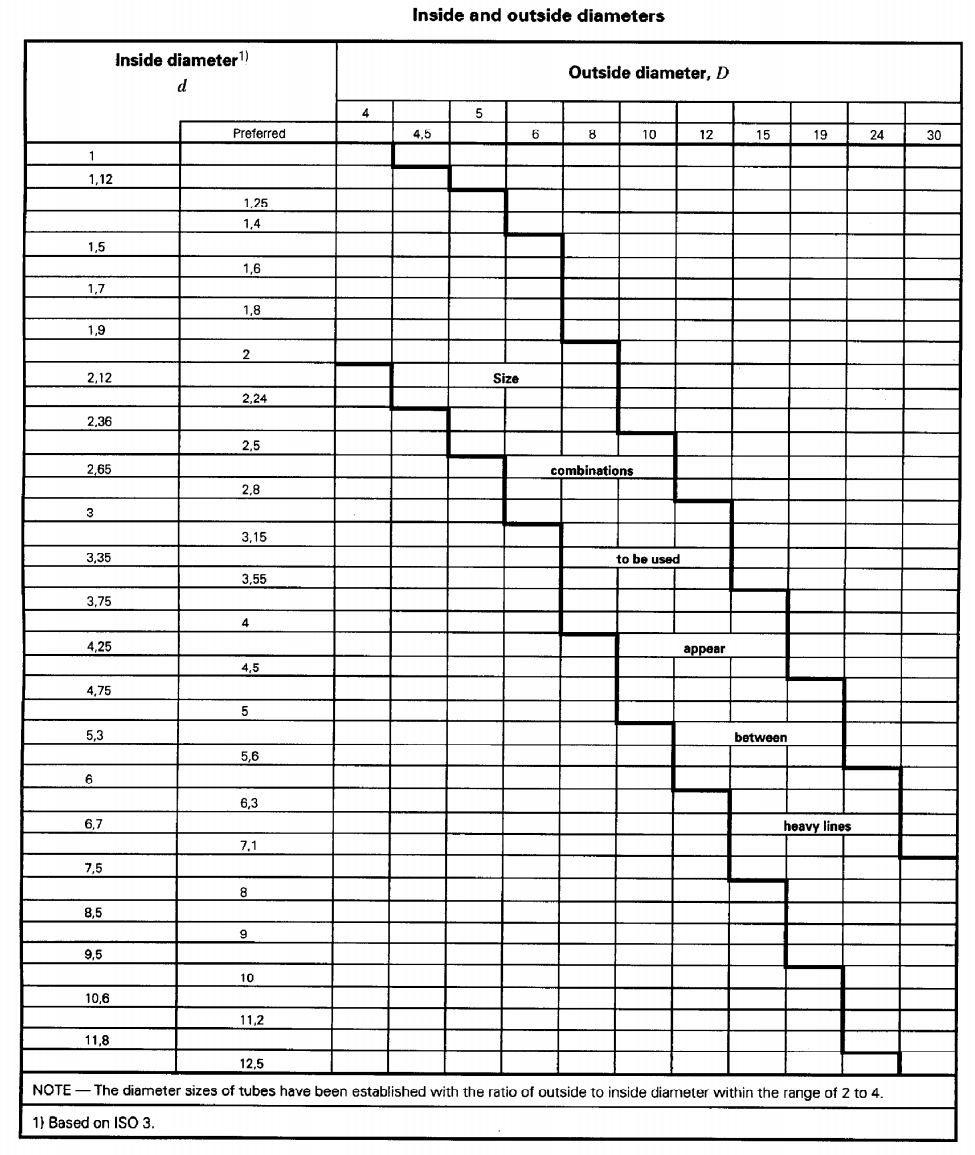

Precision Dimensional Tolerances: Engineered to precise dimensional tolerances, including outer diameter, inner diameter, and wall thickness, this steel pipe ensures seamless compatibility with fuel injection components and system integrity.

Corrosion Resistance: With its corrosion-resistant properties, the STKM11A steel pipe offers long-lasting protection against fuel additives, moisture, and environmental factors, ensuring extended service life and minimal maintenance requirements.

High Pressure Resistance: Engineered to withstand high-pressure conditions commonly encountered in fuel injection systems, this pipe provides reliable performance and safety in critical operating environments.

Application Areas

Automotive Fuel Injection Systems: Integral to fuel injection systems in automobiles, trucks, buses, and motorcycles, this seamless steel pipe ensures precise fuel delivery, optimal combustion efficiency, and compliance with emissions regulations.

Industrial Fuel Injection Equipment: Used in industrial machinery, generators, compressors, and agricultural equipment, the pipe facilitates efficient fuel injection for reliable power generation, processing, and operations across various industries.

Marine Fuel Injection Systems: Integrated into marine engines and propulsion systems, this steel pipe supports efficient fuel delivery for marine vessels, ensuring reliable performance and fuel economy in maritime applications.

JIS G3445 STKM11A OD 4mm fuel injection seamless steel pipe

Certificates: according to EN 10204 3.1

Inspection Items: Tensile stength, Yield stength, Elongation, Flattenging, Flaring

Chemical analysis

Eddy Current Test 100%, Size and surface checking 100%

Other test item can be arranged as per request

| Steel Grade | Material Number | C Max | Si Max | Mn | P Max | S Max | Cr | Mo | Tensile strength Rm (Mpa) Min | Yield Strength Reh (Mpa) Min | A Elongation(%) Min | |

| JIS G3445 | STKM 11A | - | 0.12 | 0.35 | Max 0.60 | 0.04 | 0.04 | - | - | 290 | - | 35 |

| STKM 12A | - | 0.12 | 0.35 | Max 0.60 | 0.04 | 0.04 | - | - | 340 | 175 | 30 | |

| SKTM 12B | - | 0.12 | 0.35 | Max 0.60 | 0.04 | 0.04 | - | - | 390 | 275 | 25 | |

| SKTM 12C | - | 0.12 | 0.35 | Max 0.60 | 0.04 | 0.04 | - | - | 470 | 355 | 20 | |

| STKM 13A | - | 0.25 | 0.35 | 0.3-0.9 | 0.04 | 0.04 | - | - | 370 | 215 | 30 | |

| STKM 13B | - | 0.25 | 0.35 | 0.3-0.9 | 0.04 | 0.04 | - | - | 440 | 305 | 20 | |

| STKM 13C | - | 0.25 | 0.35 | 0.3-0.9 | 0.04 | 0.04 | - | - | 510 | 380 |

15 |

Description

Key Features

Compliance with JIS G3445 Standards: Designed and manufactured in accordance with JIS G3445 standards, this seamless steel pipe adheres to strict quality control measures, guaranteeing reliability and consistency in performance.

STKM11A Grade Material: Fabricated from STKM11A grade steel, this pipe exhibits superior strength, ductility, and weldability, making it an ideal choice for demanding fuel injection applications.

Seamless Construction: Utilizing seamless manufacturing techniques, the pipe boasts a smooth internal surface and uniform wall thickness, minimizing flow resistance and ensuring uninterrupted fuel flow for optimal engine performance.

Precision Dimensional Tolerances: Engineered to precise dimensional tolerances, including outer diameter, inner diameter, and wall thickness, this steel pipe ensures seamless compatibility with fuel injection components and system integrity.

Corrosion Resistance: With its corrosion-resistant properties, the STKM11A steel pipe offers long-lasting protection against fuel additives, moisture, and environmental factors, ensuring extended service life and minimal maintenance requirements.

High Pressure Resistance: Engineered to withstand high-pressure conditions commonly encountered in fuel injection systems, this pipe provides reliable performance and safety in critical operating environments.

Application Areas

Automotive Fuel Injection Systems: Integral to fuel injection systems in automobiles, trucks, buses, and motorcycles, this seamless steel pipe ensures precise fuel delivery, optimal combustion efficiency, and compliance with emissions regulations.

Industrial Fuel Injection Equipment: Used in industrial machinery, generators, compressors, and agricultural equipment, the pipe facilitates efficient fuel injection for reliable power generation, processing, and operations across various industries.

Marine Fuel Injection Systems: Integrated into marine engines and propulsion systems, this steel pipe supports efficient fuel delivery for marine vessels, ensuring reliable performance and fuel economy in maritime applications.